Contact Details

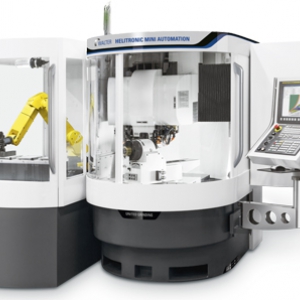

UNITED GRINDING North America has developed a new solution that simplifies the incorporation of dual gripper end-of-arm tooling on its entry-level versaLoad™ machine loader. This new I/O expansion eliminates the need for external cabling on the loader robot, streamlining dual gripper machine loading.

versaLoad utilizes FANUC’s CRX collaborative robots, which are compact, quick to implement and easy to program, but feature only two digital inputs and two digital outputs on the FANUC EE controller. A dual gripper system, which is ideal for machine tending applications, requires a minimum of four digital outputs, so adding external cabling was previously necessary. Seeking a simplified solution, UNITED GRINDING’s engineering team developed an I/O expansion interface that adds a microcontroller that talks to the serial bus.

“versaLoad is an ideal automation system for shops with a high-mix, low-volume workload, and part exchange times can be cut in half with dual grippers,” says Andreas Steiner, Automation Engineer at UNITED GRINDING North America. “Our new I/O expansion interface dramatically simplifies the use of dual grippers on versaLoad’s FANUC CRX robots and eliminates external cabling.”

The dual gripper system on the versaLoad allows manufacturers to reduce part loading times by as much as 50% when compared to a single gripper setup. This allows the automation cell to operate with maximum efficiency, enabling versaLoad users to boost productivity without having to increase headcount.

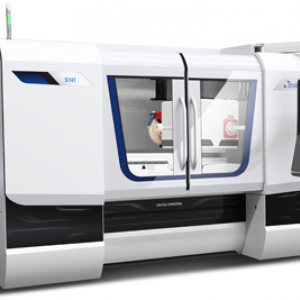

The versaLoad automation cell is compatible with several STUDER machine models, including the STUDER favorit, S33, S31, and S41.

Designed to deliver maximum machine tending versatility in a compact footprint, versaLoad lowers the automation learning curve for shops looking for a cost-effective automation solution. For more information on versaLoad or UNITED GRINDING’s other automation solutions, please contact UNITED GRINDING North America or visit grinding.com.

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- payload ( workload)

payload ( workload)

Maximum load that the robot can handle safely.

PRODUCTS

PRODUCTS