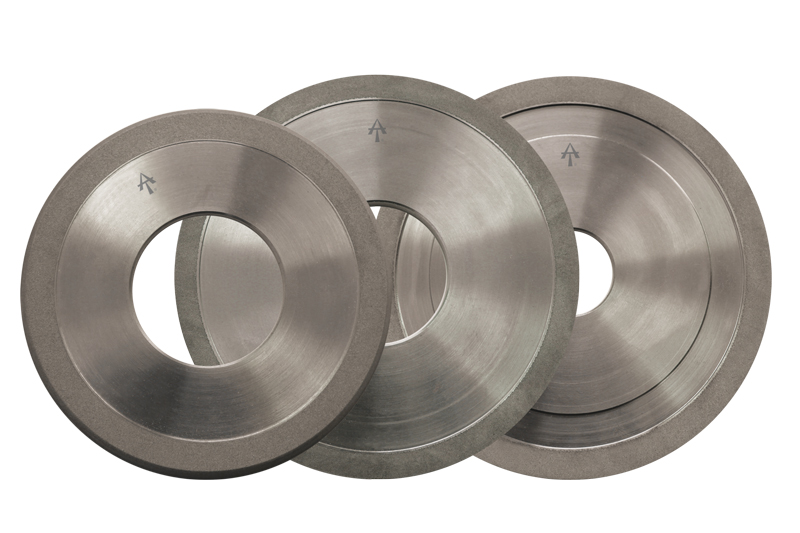

DualForce Fluting Wheels

DualForce Fluting Wheels

Abrasive Technology's DualForce fluting wheels are manufactured using the company's proprietary, controlled-structure process, which creates space between the abrasive particles, for a freer-cutting, low power-consuming wheel that withstands cutting forces generated when grinding carbide and high-speed steel. These wheels maintain high grind ratios for holding wheel shape, form and size with lower wheel wear and higher carbide removal when operators run multiple machines or lights out.

Abrasive Technology's DualForce fluting wheels are manufactured using the company's proprietary, controlled-structure process, which creates space between the abrasive particles, for a freer-cutting, low power-consuming wheel that withstands cutting forces generated when grinding carbide and high-speed steel. These wheels maintain high grind ratios for holding wheel shape, form and size with lower wheel wear and higher carbide removal when operators run multiple machines or lights out. Compatible with Anca, Guhring, Reineker, Rollomatic, Schneeburger, Star, Unison, Walter and other grinders.