Contact Details

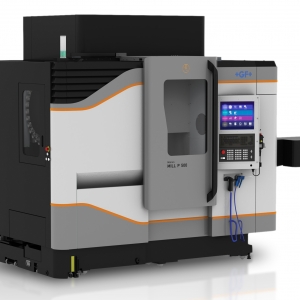

GF AgieCharmilles is redefining the wire EDM process by making its third-generation Automatic Wire Changer available on the company's latest, high-performance CUT 2000 and CUT 3000 wire-cutting EDM machines. With the optional Automatic Wire Changer, CUT 2000 or CUT 3000 operators can easily switch between different wire diameter sizes and types, optimizing both roughing and finishing operations and reducing production costs.

A manufacturer, for example, could use a larger diameter, less costly brass wire for rough passes where the emphasis is on high stock removal, and smaller diameter wire, which is often more expensive, for intricate details and fine finishing passes. The most dramatic results occur when working with parts requiring the use of wire diameters 0.004 inches (0.1016mm) or smaller.

The CUT 2000 and 3000 machines employ universal wire guide systems, enabling them to accommodate wires from 0.01 inches (0.30mm) down to 0.002 inches (0.05mm) for micro-machining and super-precision applications. The automatic wire thread and rethread capabilities of these machines also facilitate unmanned, lights-out production, and the Vision 5 numerical control on the CUT 2000 and 3000 allows for quick, easy organization and management of multiple unattended jobs. The machines are also equipped with a highly efficient digital Intelligent Power Generator, or IPG, and Variocut that provide reliable machining of even the most complex parts and for achieving surface finishes as fine as Ra 0.05µm.

Featuring compact footprints, the CUT 2000 and 3000 have rigid machine bases as well as precise integrated measuring systems for lifelong, repeatable accuracy. Both machines also manage and minimize thermal distortion generating from various machine sources, including generators and pumps, which have their own individual cooling systems. The CUT 2000 machine has X-, Y- and Z-axis travels of 13.8 inches (350mm) x 9.8 inches (250mm) x 10.1 inches (256mm), respectively. When considering the machine's fluid bath, the CUT 2000 can accommodate submerged workpieces weighing up to 440 pounds (200 kg) and unsubmerged workpieces up to 992 pounds (451 kg).

The machine also achieves taper cuts of +/- 30 degrees over 3.93 inches (100mm) in height. The larger CUT 3000 machine has X-, Y- and Z-axis of 19.7 inches (500mm) x 13.8 inches (350mm) x 10.1 inches (256mm), respectively. When considering the machine's fluid bath, the CUT 3000 can accommodate submerged workpieces weighing up to 880 pounds (400 kg) and unsubmerged workpieces up to 1,763 pounds (801 kg). The machine also achieves taper cuts of +/- 30 degrees over 3.93 inches (100mm) in height.

Related Glossary Terms

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- wire EDM

wire EDM

Process similar to ram electrical-discharge machining except a small-diameter copper or brass wire is used as a traveling electrode. Usually used in conjunction with a CNC and only works when a part is to be cut completely through. A common analogy is wire electrical-discharge machining is like an ultraprecise, electrical, contour-sawing operation.

PRODUCTS

PRODUCTS