Contact Details

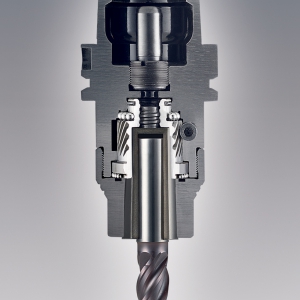

Emuge Corp. offers an extensive line of high-performance solid-carbide endmills for applications ranging from universal milling to aerospace and high hardness machining. The endmills, branded Emuge-Franken, are the result of extensive R&D and incorporate the latest in endmill technology, geometry and coatings and are designed to outperform conventional endmill offerings.

Emuge-Franken endmills are manufactured in Germany. Franken, as part of the Emuge-Franken company, has been developing and manufacturing milling tools since Emuge’s formation nearly 100 years ago.

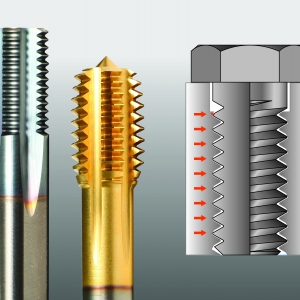

“Emuge is well known for its high quality/performance taps and thread mills, but many people are not aware that Emuge has also been manufacturing high-performance endmills since the company was founded,” said Bob Hellinger, president of Emuge Corp. “We have decided to aggressively launch a comprehensive line of high-performance mills to broaden our North American tool portfolio and meet customers’ increased demands for high-performance tools in today’s demanding applications.”

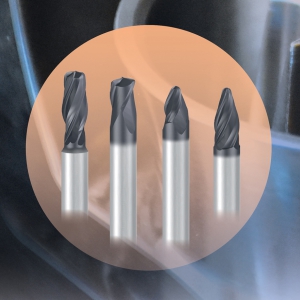

The new Emuge US/Canadian solid-carbide endmill launch includes the following tool lines:

- Top-Cut VAR, a versatile, variable helix solid-carbide inch endmill program featuring unique geometry and advanced ALCR PVD coating, for universal milling applications in virtually all materials.

- Top-Cut, metric endmills for universal milling applications with variable helix flutes and TiAlN PVD coating, ideal for both roughing and finishing operations.

- Multi-Cut, carbide roughing end mills designed with a unique serrated cutting-edge chipbreaker technology for optimal chip evacuation and can achieve metal removal rates 5-10 times that of conventional endmills, in a full range of materials.

- TiNOX-Cut, a coolant-fed roughing endmill for demanding applications such as in exotic materials and aerospace machining. Tools feature variable flute spacing and a serrated chip-breaker profile for aggressive material removal and a high heat-resistant multi-layer TiN/TiAlN coating.

- Hard-Cut endmills, specially developed for the machining of hardened materials up to 66 HRC.

Related Glossary Terms

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

PRODUCTS

PRODUCTS