EP21TDCN-LO Electrically Conductive Adhesive/Sealant

EP21TDCN-LO Electrically Conductive Adhesive/Sealant

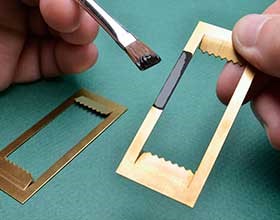

Featuring a nickel filler, Master Bond EP21TDCN-LO is an electrically conductive two-component adhesive/sealant that is particularly effective for grounding, shielding and static dissipation applications. It is a toughened system and is capable of withstanding rigorous thermal cycling, mechanical vibration and shock.

Featuring a nickel filler, Master Bond EP21TDCN-LO is an electrically conductive two-component adhesive/sealant that is particularly effective for grounding, shielding and static dissipation applications. It is a toughened system and is capable of withstanding rigorous thermal cycling, mechanical vibration and shock. This system passes ASTM E595 tests for NASA low outgassing, making it well-suited for the aerospace, electronic and specialty OEM industries, including use in vacuum and clean room environments.

EP21TDCN-LO has a low volume resistivity of 5-10 ohm-cm and a thermal conductivity of 11 Btu•in/ft²•hr•°F [1.59 W/(m·K)]. EP21TDCN-LO is dimensionally stable and bonds well to similar and dissimilar substrates such as metals, composites, ceramics and many plastics. This epoxy feature a high strength profile including a tensile lap shear, tensile and T-peel strength of 1,400 to 1,600 psi, 3,000 to 4,000 psi and 15 to 20 pli, respectively. It resists exposure to a variety of chemicals such as fuels, oils, organic solvents and water.

With a one to one mix ratio by weight or volume, EP21TDCN-LO is easy to handle with a smooth paste consistency. As a two part system, it can cure at room temperature or more rapidly at elevated temperatures. The optimal cure is overnight at room temperature, followed by 2 to 3 hours at 150 ° to 200° F. It is serviceable from -100° F to +275° F [-73° C to +135° C]. EP21TDCN-LO is available for use in ½ pint, pint, quart, gallon and 5 gallon container kits. It has a shelf life of 6 months at ambient temperatures in its original, unopened containers.