Contact Details

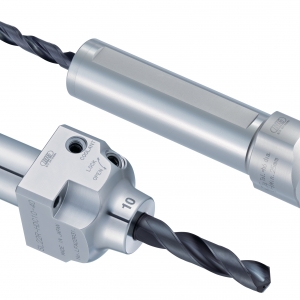

BIG Kaiser has announced the addition of the EWN 04-7 Series, reportedly the smallest precision finish boring head on the market, for use on micro-milling machines with high-speed spindles such as HSK-E25, E32 or E40.

The head features a high precision adjustment accuracy of .0005" per diameter and .0001" per diameter through the use of a Vernier scale, and a diameter range of .016" to .276" (04mm-7mm). The product is available with the Kaiser KA1 modular connection, or with a Ø10mm straight shank, and can accept boring bars with 4mm shanks. The head features a maximum through-tool coolant pressure of 300 PSI.

While this boring head is accustomed to micro-machining applications, it can also solve problems for companies that need a tool able to travel into deep cavities for ultra-small diameter boring. High rigidity and secure clamping of the boring bar makes it a good product for any micro boring application.

"The EWN 04-7 Series adds to the variety and versatility of our micro-machining program," says Jack Burley, BIG Kaiser vice president of sales and engineering. "This helps us give customers the best possible solutions for any small-diameter boring needs."

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring bar

boring bar

Essentially a cantilever beam that holds one or more cutting tools in position during a boring operation. Can be held stationary and moved axially while the workpiece revolves around it, or revolved and moved axially while the workpiece is held stationary, or a combination of these actions. Installed on milling, drilling and boring machines, as well as lathes and machining centers.

- boring head

boring head

Single- or multiple-point precision tool used to bring an existing hole within dimensional tolerance. The head attaches to a standard toolholder and a mechanism permits fine adjustments to be made to the head within a diameter range.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS