FeatureCAM

FeatureCAM

Delcam has launched the 2012 R2 release of its FeatureCAM feature-based CAM system, which includes important new strategies for roughing and turn-mill operations, alongside a range of more general enhancements to allow faster toolpath generation.

Delcam has launched the 2012 R2 release of its FeatureCAM feature-based CAM system, which includes important new strategies for roughing and turn-mill operations, alongside a range of more general enhancements to allow faster toolpath generation.

The main addition to FeatureCAM 2012 R2 is a series of new strategies for 2.5D roughing. These include a continuous spiral option to minimise wear on the cutter and machine tool, high-speed roughing options, including trochoidal machining and Delcam's patented Race Line Machining, and "tear-drop" moves to clear corners more smoothly. In addition, more styles of leads and links can now be used to give greater overall efficiency for the toolpaths.

Stepovers for 2.5D mill roughing can now be set as large as the tool diameter itself. Previously, stepovers were limited to 50 percent of the tool diameter and, if this limit was exceeded, the toolpath would leave stands. The new algorithm supports larger stepovers by providing extra moves automatically to clean up those stands.

Other milling improvements include an option to add an extra profile pass exactly at the base of flat pockets, the ability to use face-milling tools with chamfered edges to machine chamfers as well as faces and so minimise the number of tools needed, a choice of right- or left-handed thread-milling tools resulting in either climb or conventional machining of the thread, and the ability to reduce calculation times by saving boundaries as curves if they will be needed for subsequent calculations.

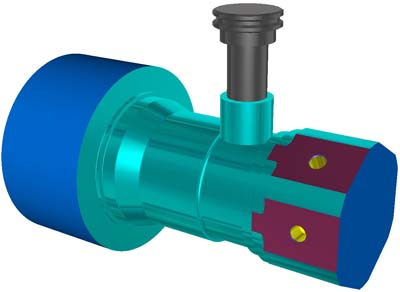

Roughing has also been improved for users of turning equipment that can operate with live tooling. A new option allows cutting with a live milling tool, while the workpiece is rotating in the turning spindle. This approach avoids the issues associated with interrupted cutting and ensures regular chip breakage, so removing any chance of wrap-around by the swarf. T

urn-mill programming has been improved with the addition of more flexible five-axis positioning. For example, any amount of negative b-axis movement available can be used, so avoiding extending the y limit too far back into the machine. Switching the positioning angles in this way makes editing easier to keep the machine within its travel limits. Another turn-mill improvement is support for cylindrical interpolation, which allows toolpaths to be created with NC code for a plane and then wrapped around a cylinder. This approach, which can also be used for four-axis milling, allows cutter compensation to be applied when calculating the toolpath and gives smaller NC code files.

All FeatureCAM users will benefit from improvements to the simulation module. In particular, they will see much faster results through the use of multiple cores for these calculations. In addition, the ability has been included to save a position during the simulation, for example, while toolpaths are being edited, and then to run the simulation from that position rather than from the start.

Other general enhancements include direct cutting and pasting of models between FeatureCAM and Delcam's PowerSHAPE design and data repair software, and the ability to create machining configurations on a network as well as on an individual computer, so saving time and encouraging consistent results from different users.