Contact Details

Tungaloy has introduced enhanced FixRMill round insert “button cutter” line that boasts impressive performance, while providing tool reliability, in copy milling of curved surfaces of stainless steel and difficult materials in 5-axis machining.

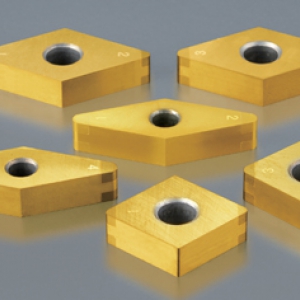

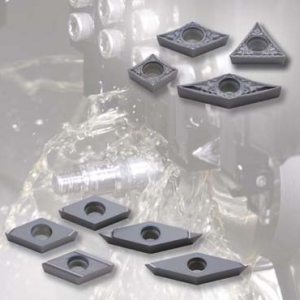

FixRMill uses round inserts for machining dies and molds, especially complex male-female main parts such as cavities and projections. The round inserts feature anti-rotation notches on the insert clearance side and matching locations on the pocket seats. These notches not only prevent the insert from rotating under heavy load but also help the operator to get a true, distinct index every time he/she goes for a new edge, allowing all of the insert to be utilized.

The round inserts are available in size 12 in two geometries: RQMT1204ENC8-MM allows up to eight indexes for 1.4 millimeter (.055″) or smaller D.O.C. and up to four indexes when used at 6.0 millimeter (.236″) D.O.C., boasting excellent per index cost; while RQMT1204ENC6-MM can provide up to six indexes for 2.6 millimeter (.102″) or smaller D.O.C. The two inserts are interchangeable for the same FixRMill cutter body.

The MM-style chipbreaker provides the cutting edge with sharpness and robustness, demonstrating exceptional reliability in varying cutting forces typically generated during copy milling operations. Two insert grades are available: versatile AH3135 grade provides excellent cutting performance over a range of material groups and AH8015 showcases superior performance in difficult materials.

This introduction includes four inserts and eight cutter bodies.

Related Glossary Terms

- button cutter

button cutter

Round insert that is able to spread the stresses generated by the cutting forces over a larger area than other insert shapes. However, a round insert generates higher axial forces, which transfer into the workpiece.

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

PRODUCTS

PRODUCTS