FlowXpert 2015 Software Suite

FlowXpert 2015 Software Suite

Flow International Corp. announced an upgrade to the FlowXpert Software Suite, FlowXpert 2015.

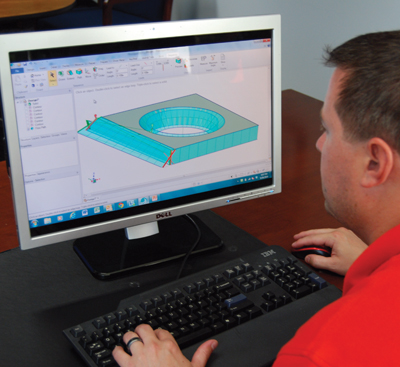

Flow International Corp. announced an upgrade to the FlowXpert Software Suite, FlowXpert 2015. This release introduces significant new capabilities for 3D pathing and cutting which allow waterjet users to work more effectively in 3D, with less complexity.

FlowXpert 2015 is a robust 3D CAD/CAM software platform that expands on the 2D FlowMaster intelligent Software Suite. The platform includes Design powered by Spaceclaim, an integrated 3D CAD/CAM programming tool with Flow Sequencer. With this release, the integrated CAD/CAM capabilities give users a seamless pathing experience. The integration with Flow Sequencer adds flexibility to users and is designed specifically for waterjet cutting, resulting in faster waterjet programming.

"FlowXpert was already a leading programming tool in the waterjet industry," says Alex Chillman, software and cutting platform manager at Flow International Corporation. "By integrating these platforms we are providing users even greater flexibility in designing and pathing; which will have great benefits for both basic and complex waterjet parts."

The software integration was engineered in partnership with Spaceclaim and takes full advantage of Flow's 40 years of waterjet application expertise. Users get faster, smarter programming that is interactive. Incorporating Flow best practices such as waterjet application tips, material cut speed knowledge, improved pathing algorithms, and expanded lead in/out customization the program estimates what steps are needed to get the best part.

"We listened to our customers to design FlowXpert 2015," continues Chillman. "The end result is a smarter system that lets users to do their work in fewer steps, with more intuitive design practices. This is powerful, straightforward 3D, and anyone can use it."

The new FlowXpert 2015 includes functions familiar for current FlowXpert users, with a redesigned interface for intuitive 3D and 2D part programming. Users can now design a part and path it in the same program. Modifying the geometry of a part is now possible without losing the path, and in most cases the Sequencer integration will automatically update the path to accommodate the changes; a feature strongly requested by customers. In addition, the software will now detect model and path errors and suggest fixes.

New capabilities in FlowXpert include:

• Integration of CAD Design powered by Spaceclaim with CAM Flow Sequencer modules.

• Waterjet specific geometry analysis means the part is ready faster.

• 3D CAM offset capabilities.

• Custom lead in/out available; or choose from an expanded lead in/out catalogue.

• Fast, versatile sheet metal processing from Spaceclaim.

• Advanced clean up tools that can be customized to your waterjet.

• Save your 3D model as a 2D programmed part.