Contact Details

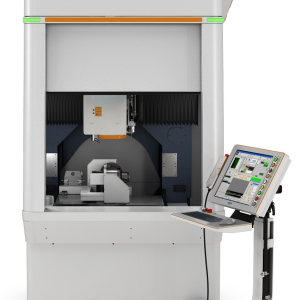

GF Machining Solutions’ new compact FORM E 350 machine is a suitable die sinking EDM solution for small shops. Even with the smallest footprint on the market, the machine still boasts several design and performance features that enhance a shop’s competitive advantage.

A sturdy C-axis construction, cross table and cast iron frame offer high stability and force reduction, which helps maintain a precise spark gap between the part and the electrode. Regardless of part weight or dielectric volume, the machine delivers consistent accuracy. Integrated glass scales preserve long-term, repeatability and eliminate the need for recalibration as well as any errors found in traditional screw systems due to backlash and wear.

The latest-generation Intelligent Speed Power Generator (ISPG) on the FORM E 350 excels at superior surface finishes and precision applications in any conductive material, according to the company. It overcomes common process challenges for copper electrodes, including electrode wear induced by electrical discharge. ISPG improves machining speeds by 40 percent and reduces corner wear by 50 percent.

Designed for high efficiency on the shop floor, the machine features a programmable dielectric management system with a 270-liter capacity integrated inside the machine cabinet. This system fills and empties the work tank without human intervention to keep the machine in production and is easy to access for routine maintenance.

The machine console comes equipped with the user-friendly AC FORM HMI (human machine interface) that is based on a standard Windows platform and offers interactive graphical assistance so that all operations, such as measurement and machining cycles, are illustrated by graphics/icons for fast operator understanding and ease of use. It provides simple descriptions of machining targets, automatic selection of optimal technology and dynamic parameters adaption.

With an X/Y/Z travel of 17.8" x 9.8" x 9.8" (350 x 250 x 250 mm), the FORM E 350 handles workpieces up to 31.5" x 19.7" x 10.4" (800 x 500 x 265 mm.) It also has a four-position linear tool changer.

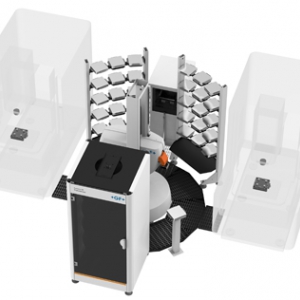

The FORM E 350 is automation ready and can easily be paired with the System 3R WorkPartner 1+ robot to implement unattended night and weekend operation.

Related Glossary Terms

- backlash

backlash

Reaction in dynamic motion systems where potential energy that was created while the object was in motion is released when the object stops. Release of this potential energy or inertia causes the device to quickly snap backward relative to the last direction of motion. Backlash can cause a system’s final resting position to be different from what was intended and from where the control system intended to stop the device.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

PRODUCTS

PRODUCTS