Contact Details

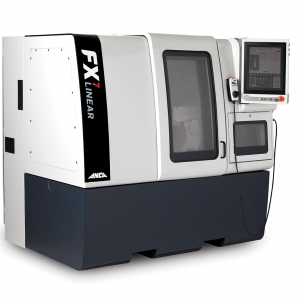

Unparalleled accuracy and exceptional quality, the FX7 ULTRA takes small tool manufacturing to new heights.

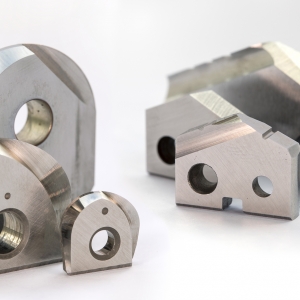

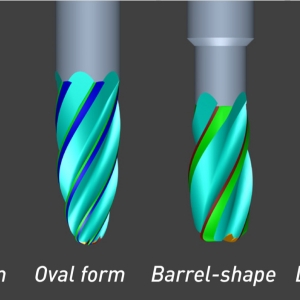

“The FX7 ULTRA introduces cutting-edge technologies that revolutionize precision grinding for small tools down to 0.1mm diameter. If you produce tools such as ballnose, corner radius endmills, and complex or intricate profile tools, then this machine is for you,” says Darren Fox, ANCA Product Manager.

New software, hardware and design features significantly improve surface finish, accuracy, and controlled runout, ensuring batch consistency from the first ground tool to the last. These advancements ensure that the FX7 ULTRA is the go-to solution for precision grinding in industries that rely on small tools, including electronics, telecommunications, medical devices, aerospace, automotive, diemold, and general machining.

Features of the FX7 ULTRA:

- one nanometer control system,

- new servo control algorithm for smooth motion,

- system and mechanical upgrades enhance stiffness and rigidity,

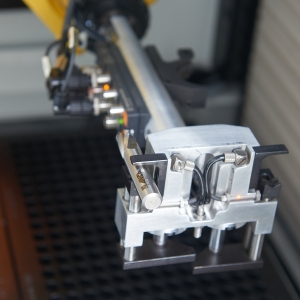

- in-process measuring, balancing and runout compensation for consistent accuracy,

- Motor Temperature Control (MTC) – ANCA’s patented innovation, and

- specialist training support from our engineering experts on how to grind perfect cutting tools.

The FX7 ULTRA not only grinds tools faster than other machines, but also produces tools with both finer surface finishes and greater accuracy — which means superior tool performance and quality.

“The ULTRA technology has enabled production of high-quality small tools with the capability to grind down to a size as small as 0.1mm. The nanometer control enables micro-adjustments for smoother axis movement resulting in optimal tool geometry, ensuring superior cutting performance and surface finish. These advancements will have a significant impact across the entire tool range, enabling precise and efficient grinding operations for a variety of applications,” Darren concludes.

Pat Boland, ANCA co-founder says: “Our customers who supply to industries where intricate and precise machining operations are paramount are always striving for the best quality tools, and now they can stay ahead of the game with the FX7 ULTRA. After years of dedicated research and development, the FX7 ULTRA is set to revolutionize the way we manufacture small tools.”

A technical look at the FX7 ULTRA’s innovative features:

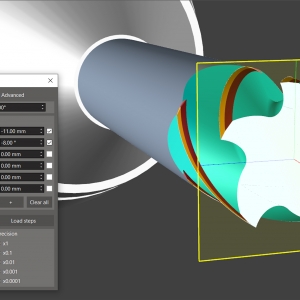

Greater control for the velocity and acceleration or deceleration along with machine jerk limits: To increase the stiffness of the C-axis, the FX7 ULTRA combines developments to the nanometer or micro degree resolution in the linear and rotary axis, tuning parameters, several system enhancements, and major mechanical changes.

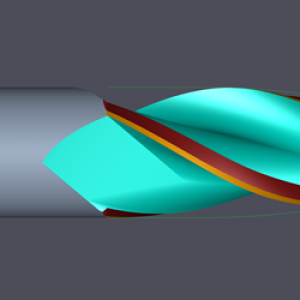

ULTRA-fast response to internal or external disturbances: ANCA’s newly designed servo control algorithm allows silky smooth motion of an axis with the use of a unique algorithm and nanometer measurement in the control system. This will create finer cutting edges and eliminating micro-chips making it more efficient while used in actual machining of materials.

Better cycle time and higher productivity of high-quality cutting tools: The unique algorithm is key to the performance of the machine and ensures outstanding tracking performance. It also allows ULTRA-performance of the servo system without using a complex, complicated, or expensive mechanical system.

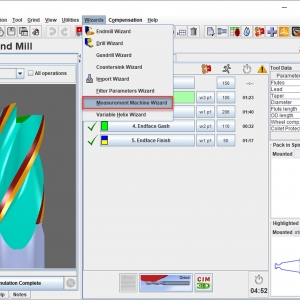

Reduces setup times and scrap: Cutting-edge software has been developed by ANCA to ensure batch consistency in large volumes. LaserUltra will maintain consistency and accuracy of the grinding process which includes in-process measurement and compensation to accommodate wheel wear and other external variations during large batch grinding. Its analog capability can maintain less than +/- 0.002mm line form accuracy of any profile which includes ballnose and corner radius tools.

Increased wheel life and better-quality tools: Tool and wheel performance can be further optimized by the iBalance software, which guides a user to the optimal grinding position and RPM for vibration monitoring and balancing the wheelpack inside the machine. Correctly balanced wheelpacks result in superior surface finish and reduced wheel wear due to the elimination of wheel vibration.

Consistency in finished tool quality: The total tool runout measurement and compensation operation is available in the iGrind software. When an endmill is in rotation it is important that each tooth hits at the exact same spot along the workpiece for longer tool life and efficient cutting. Every tool in the batch can be measured and compensated for runout to make sure the entire batch is within a tolerance of 0.002mm. It is another piece of assurance that the first endmill will be as good as the last.

Consistent spindle thermal stability: Motor Temperature Control (MTC) is a patent pending innovation built into the motor spindle drive firmware. Smart control algorithm actively manages and maintains the temperature of motorized spindles in the FX7 ULTRA. Dramatically reduced machine warmup time means production can start sooner, once the machine has reached thermal stability. This improves productivity and machine use. Consistent thermal stability of the spindle over time regardless of changes in load or speed, or coolant temperature, greatly improves the dimensional stability of grinding results.

Post grinding processes: The smoother, finer cutting edge and surface finish as a result of the combination of all the above including the nanometer control will assist in all post grinding applications like edge preparation and coating. A finer edge that has been properly prepared has greater stability, which reduces the likelihood of it chipping, while also decreasing surface roughness which can cause increased friction between the tool and the workpiece.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- edge preparation

edge preparation

Conditioning of the cutting edge, such as a honing or chamfering, to make it stronger and less susceptible to chipping. A chamfer is a bevel on the tool’s cutting edge; the angle is measured from the cutting face downward and generally varies from 25° to 45°. Honing is the process of rounding or blunting the cutting edge with abrasives, either manually or mechanically.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

PRODUCTS

PRODUCTS