Contact Details

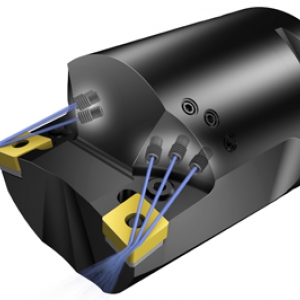

Machine shops faced with identifying ways of achieving secure machining with long and predictable insert life in steel milling operations can turn to GC1130, an insert made with the Zertivo, a unique production technology from Sandvik Coromant. GC1130 helps to overcome challenging machining conditions with a clean and intact edge, delivering high metal-removal rates and performance levels in both wet and dry machining operations. The grade is offered as the first choice for shoulder milling cutters, CoroMill 390 and CoroMill 490 and chamfer cutter, CoroMill 495.

Flaking, abrupt chipping and thermal cracks are common issues encountered when milling materials in steel applications, especially when faced with unfavorable tool paths and deep cavities or when using coolant. GC1130 has been specifically developed to help production engineers combat the subsequent unwanted effects of short insert tool life and unstable production. Manufactured with Zertivo, a unique production technology that helps amplify the grade’s benefits offering peace-of-mind through greater edge-line security and reduced flaking. Furthermore, a high-Cr content fine-grain substrate delivers high resistance to thermal cracks generated as a result of temperature fluctuations during machining, helping to ensure long and reliable tool life.

According to Mikael Eiritz, product manager for milling grades at Sandvik Coromant, “The choice of insert geometry and grade is just as important as the choice of tool when looking for secure machining. The tool and insert together is what contributes to the overall performance in an operation. Many times, when using grade GC1130, customers can move from one component to the next without having to stop production. That saves them time and money.”

When repeated shoulder milling is required, the combination of GC1130 with CoroMill 490 provides a suitably light cutting action and smooth profile that can efficiently reduce the need for a finishing operation. Also available for the CoroMill 390, this grade is best when multiple component features are required. Bringing an added dimension of security and predictability to machining in challenging conditions, the assortment includes many different types of tools and a wide selection of corner radii. Applications such as shoulder milling, linear and helical ramping, turn-milling, deep shoulder milling, edging and pocketing can be performed.

In applications where trouble-free chamfering in various steel types is required, pairing CG1130 with CoroMill 495 reduces downtime and allows for higher machine utilization. Along with the chamfering of holes and edges, typical applications include back chamfers, welding preparation and deburring.

Product manager for shoulder milling at Sandvik Coromant, Thomas Wikgren, states, “Greater process security, productivity and tool life are all within reach with GC1130. At the end of the day, our customers are looking for a reliable tool and insert combination that will help them achieve a lower cost per component.”

Related Glossary Terms

- chamfering

chamfering

Machining a bevel on a workpiece or tool; improves a tool’s entrance into the cut.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

PRODUCTS

PRODUCTS