Contact Details

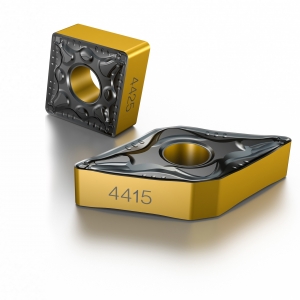

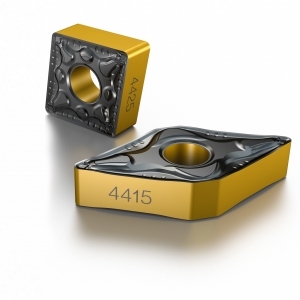

Sandvik Coromant Co. says the GC4305-grade insert maximizes metal-removal rates, shortens processing times and enhances component quality when turning steel. It is made of a heat-resistant cutting material that is suitable for dry machining, which is ideal for automotive part manufacturers that seek to avoid the stresses tools experience as a result of temperature fluctuations. The insert features the company’s wear-resistant Inveio coating.

Related Glossary Terms

- turning

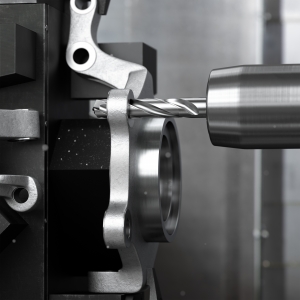

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS