Contact Details

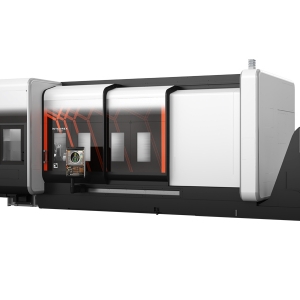

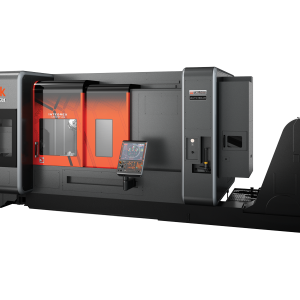

Mazak’s new HCR-5000S 5-axis, single-table (S) horizontal machining center provides the aerospace and semiconductor/high-tech industries with numerous technological innovations for efficient small- to mid-sized aluminum component processing.

The machine offers a range of high-speed spindle options, from a standard 12,000-rpm spindle up to 30,000-rpm one, and each feature an integral spindle/motor and ballscrew core cooling that minimize vibrations for higher accuracy. A 40-tool auto toolchanger, which is expandable to a 160-tool capacity, further boosts productivity with a chip-to-chip tool change time of only 2.8 seconds.

Linear roller guides allow the HCR-5000S to achieve 60-m/min rapid traverse rates, 1G acceleration/deceleration rates in the X and Y axes and 0.8G in its Z-axis to significantly shorten overall machining cycle times. Also with the guides’ low-friction, high-rigidity designs, the machine delivers aggressive feeds and speeds for everything from heavy-duty to high-speed cutting applications.

The HCR-5000S achieves unmatched precision with its single-table design that incorporates a high-rigidity bed, solid base X-axis construction and roller gear cam systems for the A and C axes. The machine’s extremely accurate tilt/rotary table provides rapid traverse rates of 50 rpm in its C axis and 30 rpm in the A-axis. The table positions in 0.0001-degree increments and accommodates parts weighing as much as 500 kg and measuring up to 700 mm in diameter and 644 mm high, depending on the cutting orientation.

In addition to full 5-axis machining capability, the tilt of the table – along with a chip conveyor and flood coolant – ensures efficient chip management and evacuation. To further optimize chip flow, the horizontal spindle orientation also makes it possible to machine a part inverted while a standard 800 L coolant tank accommodates a Niagara coolant configuration. For even higher levels of productivity and unmanned operation, the machine can be outfitted with an automatic two-pallet changer as well as a Mazak Multi-Pallet Pool (MPP) system or be incorporated into a fully automated Mazak PALLETECH System.

Mazak’s MAZATROL SmoothX CNC provides operators with ontrol of the HCR-5000S. SmoothX enables 3-D part program visualizations via its touch screen to further improve ease of use in terms of programming and program checking. Cycle times are reduced between 10 percent and 20 percent and surface finishes improved thanks to the control’s SMOOTH Machining Configuration options such as Seamless Corner Control, Active Vibration Control and Variable Acceleration.

Related Glossary Terms

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- rapid traverse

rapid traverse

Movement on a CNC mill or lathe that is from point to point at full speed but, usually, without linear interpolation.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

PRODUCTS

PRODUCTS