Contact Details

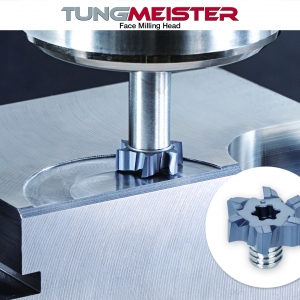

NTK Cutting Tools offers a line of high-feed cutters (HFC) for milling aluminum. This series maximizes teeth/cutter, from seven teeth on the 50mm-dia. cutter to 22 teeth on a 125mm-dia. cutter, to reduce production time.

The lightweight construction allows more customers to utilize this product (the 125mm cutter weighs only 2.4 lbs) and obtain speeds up to 20,000 rpm. The coolant-through mounting bolt provides excellent chip evacuation.

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

PRODUCTS

PRODUCTS