Contact Details

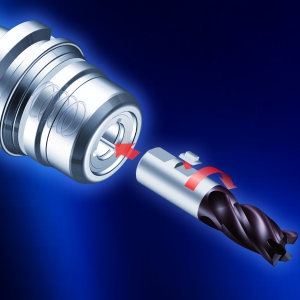

BIG KAISER has launched the HMCJ, a super-slim milling chuck with peripheral coolant supply, designed to support heavy-duty and finish endmilling tasks with power and precision using Ø1/2” or Ø12mm cutters. The newest, slimmer member of the Hi-Power Milling Chuck (HMC) family features a clamping bore with fine slots surrounded by hundreds of needle bearings, which ensures concentric, precise and smooth clamping when the nut is tightened. The HMCJ applies the highest gripping force to the cutting tool shank of any comparable milling chuck in its class, and five to six times greater compared to collet chucks, according to the company.

The slim yet rigid design of this new chuck brings the nut diameter down to 1.260” (32mm). This was achieved while maintaining a substantial cross section of 0.394” (10mm) to prevent chatter and deliver cutting security. The max jet-through coolant pressure is 70 bar.

Despite being designed for heavy cutting, the HMCJ milling chuck is able to maintain a runout accuracy of 10 microns at 4xD, giving it additional flexibility for use on finishing applications. For additional rigidity and accuracy, the CAT and BT interfaces are BIG-PLUS as standard, however, a BIG-PLUS spindle is not necessary to achieve the excellent performance of this chuck. A Ø32mm straight shank design is also available.

It is also possible to use smaller diameter milling tools through the use of PJC Reduction Collets. The Ø.500” HMCJ can then accept Ø3/8” and Ø1/4” shanks, and the Ø12mm HMCJ can accept Ø10mm, Ø8mm and Ø6mm shanks.

“Our new HMCJ delivers a market-leading combination of power and precision,” says Jack Burley, vice president of sales and engineering at BIG KAISER. “For heavy cutting and milling applications, it provides all the rigidity and accuracy needed.”

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- endmilling

endmilling

Operation in which the cutter is mounted on the machine’s spindle rather than on an arbor. Commonly associated with facing operations on a milling machine.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS