HyperMILL 2022.1 CAD/CAM Software Suite

HyperMILL 2022.1 CAD/CAM Software Suite

Highlights in hyperMILL® 2022.1 include a new break-edge function for contour milling, combined pocket milling together with a finish path allowing cutter compensation, and increased efficiency for 3D plane machining. The new automated 3D plane machining strategy improves machining quality by searching for suitable, high performance path layouts according to parameters including when adaptive pockets are present.

OPEN MIND Introduces New, Powerful Functionality in

hyperMILL® 2022.1 CAD/CAM Software Suite

OPEN MIND Technologies a leading developer of CAD/CAM software solutions worldwide, has introduced its latest hyperMILL® 2022.1 CAD/CAM software suite which offers users new and enhanced features for even more powerful NC programming in applications ranging from 2.5D to 5-axis. "Continually improving programming efficiency and providing ways to save preferred routines is critical for enriching and streamlining the operator experience," said Mr. Alan Levine, Managing Director of OPEN MIND Technologies USA, Inc. "The latest features and enhancements in hyperMILL® give users increased convenience and faster programming tools."

2D, 3D Strategies and Tool, Job Efficiencies

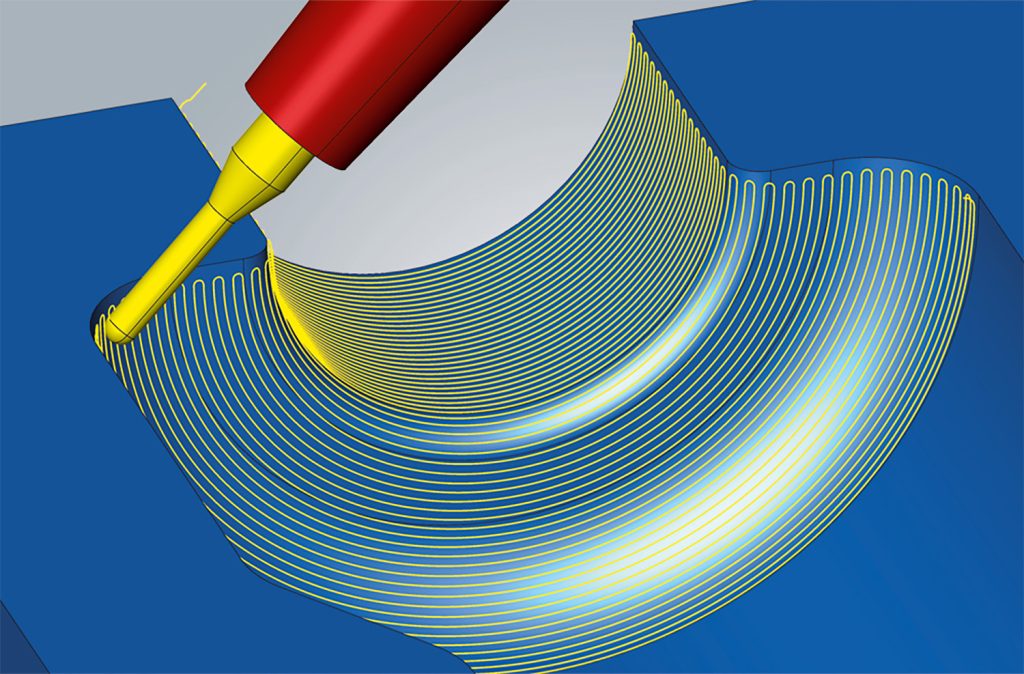

Highlights in hyperMILL® 2022.1 include a new break-edge function for contour milling, combined pocket milling together with a finish path allowing cutter compensation, and increased efficiency for 3D plane machining. The new automated 3D plane machining strategy improves machining quality by searching for suitable, high performance path layouts according to parameters including when adaptive pockets are present.

For improved tool data reliability and time savings, tool data such as length, radius, corner radius, and tool number and name, can be transferred directly from hyperMILL® to a Heidenhain TNC640 control using the hyperMILL® CONNECTED Machining module. Now it is possible to import calibrated tools from a tool management system into hyperMILL® to create programs, and then transfer the tool list or individual tool data to the machine.

Blow Molding & Tube Machining Developments

Five-axis radial machining strategy for blow molds has been enhanced to better handle steep areas and undercut regions, and to adapt to 3-axis machines as required. For

5-axis Tube Finishing, there have been several enhancements to improve machining quality and simplify programming.

Expanded Virtual Machining Capabilities

Improved linking logic in hyperMILL® VIRTUAL Machining Optimizer for 5-axis table-table machines is now offered. The VIRTUAL Machining Optimizer module links individual part programs with smooth and safe connections. An "Optimized Table-Table Logic" option allows users to select a distance value and the Optimizer automatically calculates the safety distances using the raw part, component and clamps selected in the job list. The defined distance is maintained between all components, and movement sequences are automatically optimized.

Virtual Meets Additive

A new VIRTUAL Machining capability for Additive Manufacturing processes, where machines often have limited axis ranges, is available in hyperMILL® 2022.1. Now hyperMILL® VIRTUAL Machining Optimizer can be used during NC code generation to simulate additive tool paths to optimize them for the machining.

Time Savings in EDM

Enhancements to CAD functions and the integrated hyperCAD®-S Electrode module allow users to control the traverse path during the EDM eroding process and eliminate the need to program on the controller. Movement sequences can be simulated with the hyperMILL® SIMULATION Center and checked for collisions.

Mill-Turn Enhancements

New extensions to the hyperMILL® MILL-TURN capability include more streamlined programming and simulation processing and management for machines with main and counter spindle configurations. The jobs are simply programmed in one job list under the "main spindle" and "counter spindle" containers, which assigns them to the respective machining side. The component or bar material, with or without parting, is easily transferred with the new transfer job. NC output from the main side, opposite side, and component transfer are realized in one end-to-end NC program with one machine model and post-processor. This process is initially available for DMG Mori CTX machines with a Siemens control. Also, component areas for turning or grooving are reliably recognized, structured and displayed as programming features. hyperMILL® automatically divides the recognized features into several areas that can be turned, faced, groove machined, or machined with a combination of these technologies, saving significant time while giving users full access to all recognized contours.