KRGU and GHS Grinding Steady Rests

KRGU and GHS Grinding Steady Rests

Kitagawa NorthTech Inc. introduces a new series of grinding steady rests. The grinding steady rests feature two models supported with turnkey design, build and installation capabilities dedicated to grinding applications. The new fully retracting KRGU steady rests and GHS steady rests are suitable for grinding camshafts, crankshafts and other cylindrical applications where accuracy and repeatability are essential.

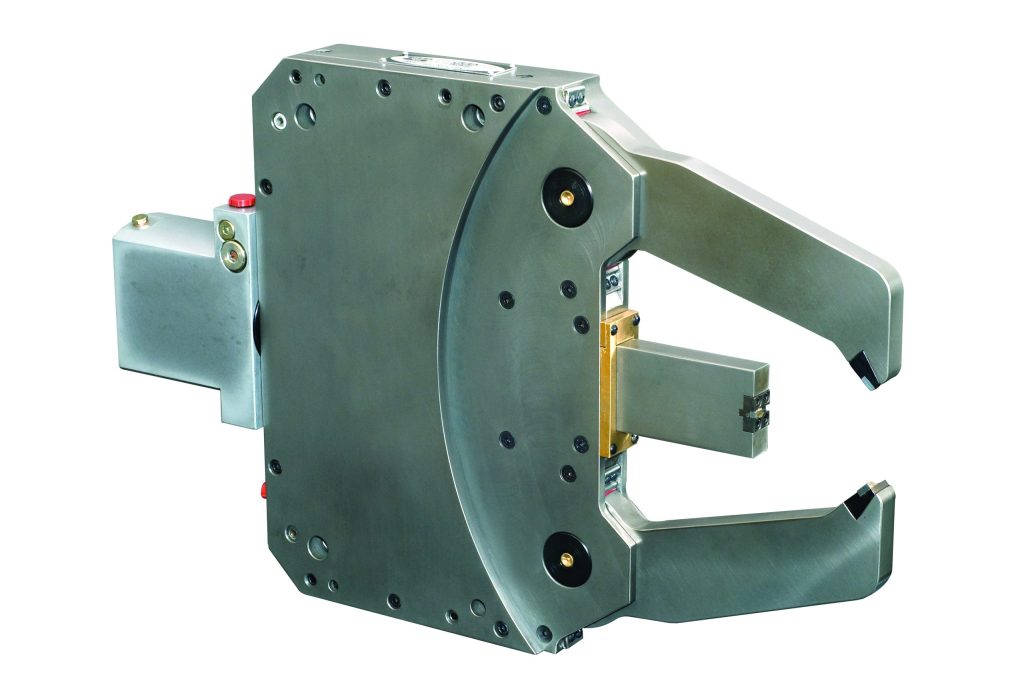

Kitagawa NorthTech Inc. introduces a new series of grinding steady rests. The grinding steady rests feature two models supported with turnkey design, build and installation capabilities dedicated to grinding applications. The new fully retracting KRGU steady rests (pictured) and GHS steady rests are suitable for camshafts, crankshafts and other cylindrical applications where accuracy and repeatability are essential.

Steady rests are a critical requirement for the grinding camshafts, crankshafts and other relative geometries. When the piece length increases relative to the diameter it becomes unstable and will deflect under the grind load. Kitagawa NorthTech says the use of its grinding steady rests will eliminate the problems of part deflection, grind surface finish and centering accuracy.

The KRGU series steady rests are specially designed for crankshaft grinding to accommodate the maximum eccentric throw and journal diameter of crankshafts. Custom designs are available to accommodate automated loading. Available in standard gripping diameters from 2.75" (70 mm) to 7.5" (190 mm).

Key features and benefits include:

• Retractable body using guide ways

• Suitable for all crankshaft, camshaft and cylindrical grinding applications where high eccentric throw is a requirement

• High accuracy, with three-point finely adjustable centering capability

• Modular regrindable carbide or relappable PCD work rest pads

• Works well with retracting in-process gaging (IPG)

The GHS series general-purpose steady rests are for all standard and automated grinding applications, such as cylindrical grinding, camshaft grinding and camlobe grinding. Available in standard gripping diameters from .394" (10 mm) to 4.724" (120 mm).

Key features and benefits include:

• Suitable for all crankshaft, camshaft and cylindrical grinding applications

• High accuracy, with three-point finely adjustable centering capability

• Modular regrindable carbide or relappable PCD work rest pads

• Works well with retracting in-process gaging (IPG)