Contact Details

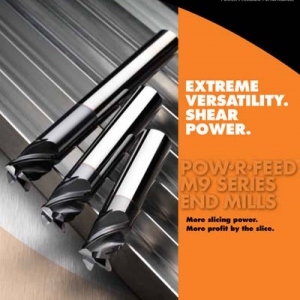

IMCO Carbide Tool Inc. has developed a new series – M936 POW-R-FEED end mills – designed for faster part cycles and speeds never seen before with IMCO legacy tools, regardless of machining stations’ horsepower.

“This is the cutter for any programmer machining steels, stainless steels and titanium on 3-axis to 5-axis CNC machining centers that wants to run fast and helical enter, ramp, slot and peripheral mill at fantastic feed rates,” said Matt Osburn, Vice President, Technical Director for IMCO.

“The M936 is designed for very aggressive traditional tool paths, stepovers and depths beyond the reach of any of the industry’s legacy tools,” Osburn said. “It’s IMCO’s free-est cutting end mill in steels to date.”

“Our goals were higher running speeds, free cutting action and the highest metal removal rates we could achieve,” Osburn said. “We redesigned and reimagined every aspect of the original POW-R-FEED series to maximize free cutting action, facilitate maximum speed and metal removal, and extend tool life in the metals our customers work with most.”

The M936 maximizes the output of machines most customers use, explained Steve Avers, IMCO’s Technical Support Manager. With conventional low-horsepower machines, this free cutting action means the M936 cutter can run to the machine’s upper capacity limits.

Change tool path moves without slowing.

“Users can make various tool path moves without slowing down,” Avers said, “so they get faster cycle times and more production.” When a 5-axis machine can swing an end mill around in all directions without clogging, the machinist can complete the operation with one chucking, saving a lot of time.

Unique flute and core geometries achieve extremely aggressive cutting parameters. The proprietary end face allows very aggressive ramping and helical entry parameters. A super-tough carbide core and an ultra-modern AlTiSN slippery-smooth coating prevent chip buildup and allow higher feeds and metal removal rates.

“Combined,” Osburn said, “these features make the tool virtually impossible to clog,”

Tool life is exceptional, thanks to the variable helix and variable index effects on vibration damping, the specially engineered carbide grade and ultra-modern coating.

The M936 is a very affordable alternative to competitors’ high-performance tools for machining these metals, Osburn said, “and the price-to-performance ratio is exceptional.”

“We do whatever it takes to give our customers the edge and help them achieve higher productivity and profitability,” Osburn said. “That’s what we do best.”

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

PRODUCTS

PRODUCTS