Contact Details

ANCA’s new Management Suite provides customers the technology to monitor the performance of their machines remotely and enables companies to run smart factories by providing live production information to make data-based decisions for operational improvements. Management Suite monitors machine and production in real time and delivers up-to-date information, enhancing visibility and control in manufacturing operations, reduces costly machine down-time by immediately notifying when a machine has ceased production, with reasons for the stoppage via an email or SMS to the relevant personnel. And provides complete visibility of the machine status and activity from the office PC or from anywhere in the world if the user is logged into the company’s server.

For a demonstration, see https://www.youtube.com/watch?v=t8zYEAaeClE

Thomson Mathew, ANCA software product manager, said, “Grinding machine owners are looking for the ability to remotely monitor machines for better intelligence on grinding performance and down-times in high-volume production.”

CNC grinding machines are often setup to produce over weekends when the plant is not occupied. Management Suite avoids the need to staff on weekends as it allows a team to monitor production, getting immediate notification if trouble occurs. This ability supports production with minimal interruption.

Data analytics are the key to improving business processes and this new software suite has been designed to provide as much intelligence as possible on machine performance in a simple to use interface. The machine analytics provided by ANCA Management Suite can be used to produce highly accurate reports on machine usage, helping to reduce waste and increase overall equipment efficiency.

ANCA Management Suite includes:

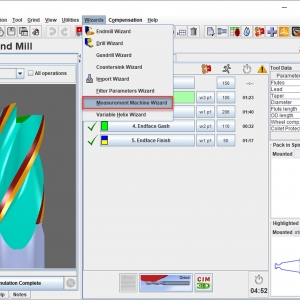

• Tool Management maintains revision control of your grinding programs allowing you to easily revert to older versions. You can also visually identify program changes using the file difference tool.

• Wheel Management is a central inventory for wheels and wheel packs. It provides a platform to easily share wheel packs and qualification data between machines. It also has a handy search function so that operators can easily find what they are looking for. Another key feature of the Wheel Management product is the differentiation between simulator qualified wheels which prevents the usage of actual wheels on machines to avoid collisions and damages to machine and wheel packs.

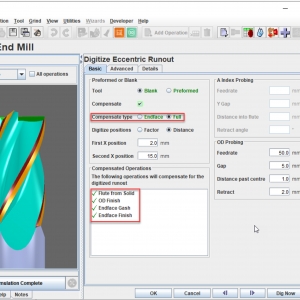

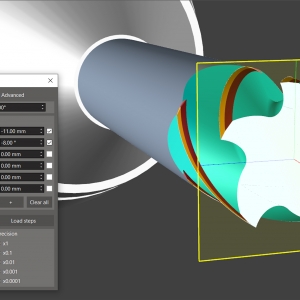

• RedaX is a remote data analytics real time monitoring solution for machines. Its open platform communication unified architecture is part of RedaX and runs on machines to monitor and broadcast machine data. From this the client, can consolidate the findings on a web page that is displayed in a real-time web browser.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

PRODUCTS

PRODUCTS