Contact Details

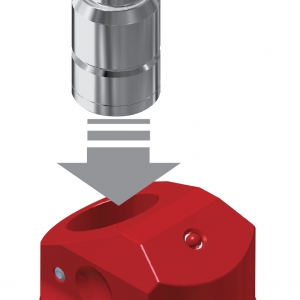

BIG Kaiser now offers BIG Daishowa's high precision Mega ER Grip with the KAISER modular KAB connection, allowing custom collet chuck configurations with standard components.

The Mega ER Grip was designed to perform in the four most critical areas of tool holder performance: clamping force, concentricity, rigidity and balance at high spindle speeds. These factors, combined with the system's reliable and stable runout accuracy, amount to significant long-term savings, according to the company. A major design feature increases the contact length of the internal taper of the chuck body, reducing the undesired overhang of the collet for significant performance increases.

All components of the Mega ER Grip system are manufactured with BIG Daishowa's high-precision production technology; high rigidity body, precision notch-free nut and AA grade ER collet. BIG's ER collets are made in accordance with DIN6499 and ISO15488 standards and feature the best runout accuracy in the world, hitting a guaranteed 0.00012" (3µm) at 5xD. Additionally, by utilizing the Mega ER Perfect Seal, coolant can be securely delivered through-tool or directed to the cutter periphery.

Now, with the addition of the modular KAB connection, KAISER modular tooling system users have a high precision collet chuck option to use with existing KAISER KAB accessories, like shanks and extensions/reductions. Furthermore, users can make this high precision ER collet chuck as long or as short as they want since the original integral design only averaged a maximum gauge length between six and seven inches.

"This is great for job shops looking to avoid dedicated, one-size-fits all tool holders, it allows flexibility to build a custom tool with standard components," says Jack Burley, VP of sales and engineering, BIG Kaiser. "The KAB connection is an extremely rigid modular connection with very accurate ground mating surfaces and the KAB pin for torque transmission."

The Mega ER Grip with is offered in KAISER KAB4, KAB5 and KAB6 connections and can be adapted to any shank and gauge length with the KAISER modular connection. The clamping diameter available is .075" to .787" with the usage of ER16-32 collets.

Related Glossary Terms

- arithmetic average ( AA)

arithmetic average ( AA)

The mathematical expression denoting one of several parameters that describe surface texture (same as average roughness Ra). Average roughness is the arithmetic average height deviation of the measured surface profile from the profile centerline. See surface texture.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- modular tooling

modular tooling

1. Tooling system comprised of standardized tools and toolholders. 2. Devices that allow rapid mounting and replacement of tools. Commonly used with carousel toolchangers and other computerized machining operations. See toolchanger; toolholder.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS