Contact Details

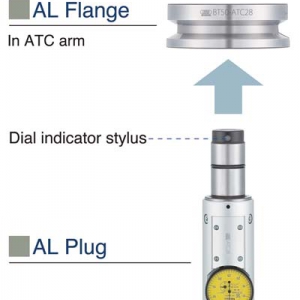

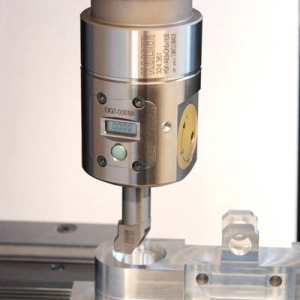

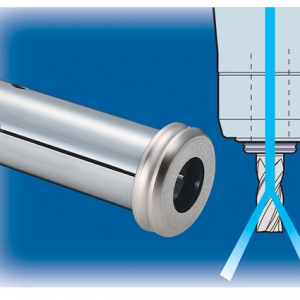

BIG Kaiser Precision Tooling Inc. has introduced Mega ER Grip, a new premium ER collet chuck system featuring a runout accuracy of .00012" (3µm) at 5xD. The Mega ER Grip was designed to outperform all other ER systems in the four most crucial areas of tool holder performance: clamping force, concentricity, rigidity and balance at high spindle speeds. These factors, combined with the system's reliable and stable runout accuracy, amount to significant long-term savings. A major design improvement increases the contact length of the internal taper of the chuck body, reducing the undesired overhang of the collet for significant performance enhancements.

"Our tests have shown that Mega ER Grip performs exceedingly well in these four areas," says Jack Burley, BIG Kaiser vice president of sales and engineering. "The result is cost and down-time reduction thanks to longer tool life. Customers will also see improvements in machining quality and shorter production times because of reduced cutting vibrations."

All components of the Mega ER Grip system are manufactured with BIG Daishowa's production technology: a high-rigidity body, a precision notch-free nut and an AA-grade ERC collet. ERC collets are in accordance with DIN6499 and ISO15488 standards and feature a clamping range of .075" to .787" in diameter.

With the Mega ER Perfect Seal, coolant can be delivered through the tool or to the cutter periphery. Tapped holes around the body periphery promote precision balancing, and the system is only available with dual-contact BIG-PLUS (CAT), HSK and CAPTO interfaces to ensure maximum rigidity.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

PRODUCTS

PRODUCTS