Contact Details

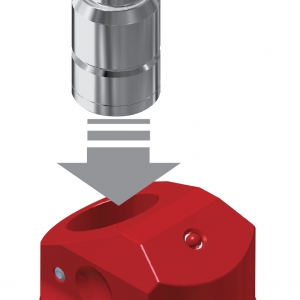

BIG KAISER’s Mega New Baby Chuck is now available up to 1"-dia. clamping for drills, reamers and finishing endmills with 0.00004" runout accuracy. The Mega New Baby Chuck is a high precision and multiple-purpose collet chuck system. It is designed for high-speed cutting and guarantees a 1 micron runout at the collet nose.

The Mega New Baby is suitable for cutting tools with a diameter up to 25.4 mm and its high-speed design is offered in six different collet series sizes. These precise and versatile collet chucks are well accepted and recognized for their accuracy in high-speed applications.

Ideal length and diameter of the holder is the key to precision machining. If selection is limited, an increased tool extension reduces performance. BIG KAISER has 353 different versions available as standard, making it easier to select the perfect one.

Mega New Baby Chuck 25N has a clamping range of 0.610"-1.000" in diameter. The thrust ball bearings eliminate distortion of the collet during tightening and the patented design prevents the ball bearings from moving at high speed.

Additional features include:

- Available in BIG-PLUS (SK/BT), HSK and BIG Capto

- Two-way coolant supply: Through tools or jet if tools don’t have any holes

- High runout precision of 0.003mm at 4xD

- Every chuck is 100 percent inspected twice

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- micron

micron

Measure of length that is equal to one-millionth of a meter.

- precision machining ( precision measurement)

precision machining ( precision measurement)

Machining and measuring to exacting standards. Four basic considerations are: dimensions, or geometrical characteristics such as lengths, angles and diameters of which the sizes are numerically specified; limits, or the maximum and minimum sizes permissible for a specified dimension; tolerances, or the total permissible variations in size; and allowances, or the prescribed differences in dimensions between mating parts.

PRODUCTS

PRODUCTS