Contact Details

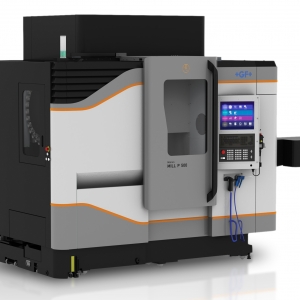

GF AgieCharmilles' Mikron HSM 20U LP (linear performance) milling machine is available in 3- and 5-axis versions and can produce parts via simultaneous 5-axis high-speed machining. The machine's 50,000-rpm, 11.4-hp Step-Tec spindle assists in imparting surface finishes as fine as 0.05µm Ra. The machine has linear motors for the main machine axes and direct-drive motors for the B and C axes.

According to the company, the machine easily fits into most facilities, which is critical for dental laboratories, watchmaker shops and other locations that produce small, complex components where floor space is often limited. Gisbert Ledvon, director of business development for North America, noted the milling machine accommodates the medical industry's increased need for lean manufacturing via small-footprint, high-speed machines.

To counteract the high levels of heat that can develop over prolonged periods of high feed rates, the machine employs a thermal management system. Each of the linear axes features a cooling unit to systematically draw the heat from the machine, creating geometric stability and high repeatability of movement guidance.

The machine has Intelligent Tool Measurement to avoid inconsistent loading of small tools and 3-D geometry errors because of inaccurate measurement of these tools. ITM records the complete tool tip up to a diameter of 0.47" on image sensors.

Related Glossary Terms

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- lean manufacturing

lean manufacturing

Companywide culture of continuous improvement, waste reduction and minimal inventory as practiced by individuals in every aspect of the business.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

PRODUCTS

PRODUCTS