Contact Details

If you’ve ever struggled with inserts coming loose during a slotting operation, keep reading. How about inconsistent slot widths, fumbling with awkward screws and inserts on a slotting cutter, or having to use a piece of shim stock to pry wedged chips from deep inside a slotted workpiece? These are just a few of the problems machinists face when trying to cut narrow slots and grooves, but thanks to the newly introduced Kennametal Narrow Slotting (KNS) cutter, the days of “slotting dread” are over, according to the company.

Slotting is a common machining practice. Scott Etling, Kennametal’s director of global product management for indexable milling, lists many applications where the KNS excels. Automakers can use the new cutter to separate cast exhaust manifolds and steering components. Equipment manufacturers can cost-effectively mill the clamping slots on shaft supports and stock collars. Power generation and electronics companies now have a more productive way to machine keyways, add heatsink grooves, yokes and O-ring grooves.

“This tool is a game changer in a number of situations,” Etling says. “Customers can mount a series of KNS cutters on an arbor called “Gang Milling” to either machine multiple grooves at once or conduct multiple cutoff operations. This tool can also be used to remove five-axis machined or 3D-printed parts from their base material. And since raw material prices continue to increase, our customers wish to machine away as little material as possible. Here it’s beneficial to use the narrowest slotting cutter possible to reduce waste. KNS does that.”

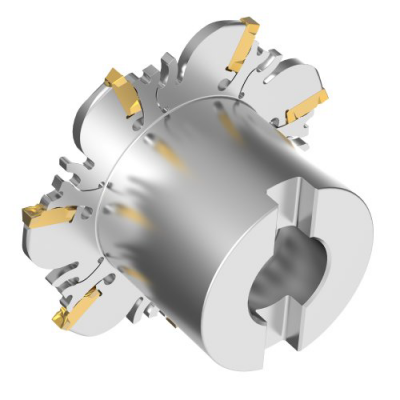

The KNS has a double-V design for secure insert retention. A combination of radial and axial positioning not only improves tool life but part accuracy as well. The insert range accommodates slot widths from 1.6 mm to 6.4 mm (0.063 in. to 0.250 in.). Inserts are available in single- or double-ended cutting edges with either a flat or full radiused cutting edge. The cutter diameters range from 63 mm to 250 mm (2.5 in. to 10 in.), and depending on the body size,

arbor or shell mounting (or both) is possible.

“We're really excited about this new design,” he says. “It’s stronger and more accurate than competing solutions and reduces tooling costs as well. Customers can use both ends of a double-ended KNS insert on shallow slotting applications, then move to a single-ended insert when they need the additional depth. It definitely offers a lot of value.”

These features already give Kennametal a substantial lead over the competition in the narrow slotting market, but the benefits don’t stop there. There’s also the carbide. Tim Marshall, senior global product manager for indexable milling, notes that Kennametal has made significant improvements in grade technology recently, and that the KNS leverages these developments.

“With the KNS program we offer three insert grades,” he says. “KCU25 and KCPM40 are multiphase PVD grades that provide excellent edge stability and wear characteristics in steels, stainless steels and high-temperature alloys, even at elevated feeds and speeds. While KCPK30 is a CVD-coated grade suitable for rough milling and general machining of steels and cast iron.”

Good carbide is important, but so too is the insert geometry. Thanks to a positive rake geometry and special edge preparation, the KNS inserts are free cutting without sacrificing the edge toughness needed in most slotting applications. What’s more, the SGP geometry promotes excellent chip flow, curling even the stringiest materials into tight, easily-evacuated Cs and 9s. This means you can put the shim stock and home-made chip hooks back in your toolbox.

The KNS is also easy to use. The innovative, symmetrical Easy-X wrench design means no more digging in the chip pan for lost screws and inserts, no more wedges or clamps to misplace—just pop the wrench into the cutter body, give it a twist, and the insert is easily replaced, even in tight quarters. Each cutter body and wrench are also clearly marked, so there’s no chance of damaging the cutter body by using the wrong tool.

Last but not least the integral hub design. This eliminates the need for drive rings and washers, and greatly contributes to the system’s repeatability and accuracy. And because the hub has dual keyways, the cutters can be staggered in gang-milling scenarios, reducing cutting forces and generating a smooth cutting action.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- arbor

arbor

Shaft used for rotary support in machining applications. In grinding, the spindle for mounting the wheel; in milling and other cutting operations, the shaft for mounting the cutter.

- cutoff

cutoff

Step that prepares a slug, blank or other workpiece for machining or other processing by separating it from the original stock. Performed on lathes, chucking machines, automatic screw machines and other turning machines. Also performed on milling machines, machining centers with slitting saws and sawing machines with cold (circular) saws, hacksaws, bandsaws or abrasive cutoff saws. See saw, sawing machine; turning.

- edge preparation

edge preparation

Conditioning of the cutting edge, such as a honing or chamfering, to make it stronger and less susceptible to chipping. A chamfer is a bevel on the tool’s cutting edge; the angle is measured from the cutting face downward and generally varies from 25° to 45°. Honing is the process of rounding or blunting the cutting edge with abrasives, either manually or mechanically.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

Additional Products from Kennametal Inc.

Pagination

- First page

- Previous page

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

PRODUCTS

PRODUCTS