Contact Details

Sandvik Coromant customers can now customize a cutting tool online without having to speak to a company sales representative. The time to place an order for customized tooling solutions is reduced substantially as a result, which in turn reduces overall tool delivery time.

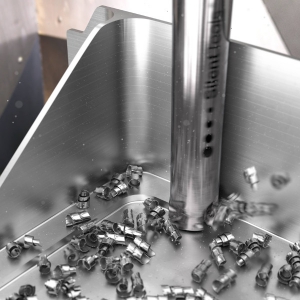

Many manufacturers benefit from using cutting tools that are not available “off-the-shelf." The most common example is when a specific, non-standard hole diameter is specified. Producing such a feature typically entails an initial drilling operation, followed by boring to the required size. However, by applying a small modification to an existing off-the-shelf drill, the manufacturer could create the hole according to specification using just one drill.

Previously, the process of quoting and ordering customized solutions required either downloading, completing and sending in a physical form, or consulting with a Sandvik Coromant sales representative. As of April 1, 2019, however, any registered Sandvik Coromant web user will be able to log in and start using the newly developed feature in their browser for free. The user can click through a few guided steps and customize a standard cutting tool to match specific requirements. In the final step of the process, the user simply places the order.

“The world of manufacturing is changing, with an increasing need for greater flexibility in tooling,” says Brian Davis, manager of global sales processes, Sandvik Coromant. “This trend also impacts cutting tool suppliers. Offering customized cutting tools demands the development of advanced processes, and making this customization option available to all our customers is a bold move, but one we know offers multiple benefits.”

Clearly, a faster tool customization process translates directly into faster tool delivery, all without losing time in conversation with sales representatives.

Further advantages include the availability of a larger number of products on the web (beyond standard products), as well as a new opportunity to review any customized products sent via sales representatives.

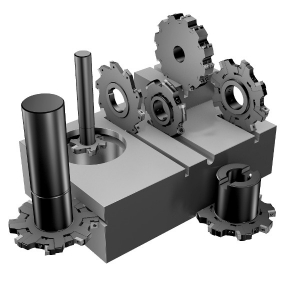

In addition to drills, the new online service applies to parting and grooving, milling and tooling systems products.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

PRODUCTS

PRODUCTS