Contact Details

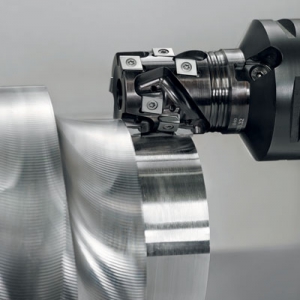

Walter has expanded the range of its Paradur® Ti Plus and Paradur® Ni 10 and Prototex® TiNi Plus tap lines, specifically by increasing its existing portfolio for J profiles with extensive new dimensions. Screw threads with J profiles feature a root radius, which improves the tensile stress area of the fastener and helps reduce the stress concentration factor in the thread to make the thread stronger. The minor diameter of J-profile threads is curved to minimize stress points created by sharp edges or corners, which can break due to vibration. Threads with the J profile are particularly preferred in the aerospace industry for difficult-to-machine materials.

Paradur® Ti Plus and Prototex® TiNi Plus taps are now available to produce UNJC4 – UNJC3/8, UNJF6 - UNJF5/8 and MJ3 to MJ10 thread sizes, and the Paradur® Ni 10 taps are available to produce UNJC4 – UNJC3/8, UNJF6 – UNJF7/8 and MJ3 to MJ6 .

The Paradur® Ti Plus taps are for threading blind holes with a geometry specially developed for machining titanium alloys with a tensile strength of at least 700 N/mm2 using emulsion instead of oil. The tool has a wear-resistant, titanium-free ACN coating to prevent built-up edge, a 15° helix angle with chamfer form C, and an enlarged core diameter for a high level of stability and process reliability. The Paradur® Ti Plus tap performs up to 2×DN in the standard range. Potential benefits include a high level of process reliability because of elevated tool stability, long tool life because of the hard coating and stable cutting edges that prevent fractures.

The Paradur® Ni 10 taps are also for threading blind holes. Walter specially developed the geometry for tapping nickel-based super alloys, such as Inconel 718, with a tensile strength up to 1,450 N/mm2. The uncoated tool is also cost-effective when tapping stainless steel with difficult cutting properties and steel with a tensile strength from 1,200 to 1,600 N/mm2. The cutting edges are stable due to the reduced 10° helix angle in the chamfer section. The usable length is up to 1.5×DN in the standard range.

The Prototex® TiNi Plus tap is effective for through-hole threading. Walter specially developed the geometry to thread titanium and nickel-based super alloys (ISO S material group) with a tensile strength of 700 N/mm2 or higher using emulsion. It provides effective depths to 2×DN in the standard range. In addition to aerospace components, the Prototex® TiNi Plus tap excels threading components for the medical device industry

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- built-up edge ( BUE)

built-up edge ( BUE)

1. Permanently damaging a metal by heating to cause either incipient melting or intergranular oxidation. 2. In grinding, getting the workpiece hot enough to cause discoloration or to change the microstructure by tempering or hardening.

- emulsion

emulsion

Suspension of one liquid in another, such as oil in water.

- helix angle

helix angle

Angle that the tool’s leading edge makes with the plane of its centerline.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- tensile strength

tensile strength

In tensile testing, the ratio of maximum load to original cross-sectional area. Also called ultimate strength. Compare with yield strength.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.

PRODUCTS

PRODUCTS