Contact Details

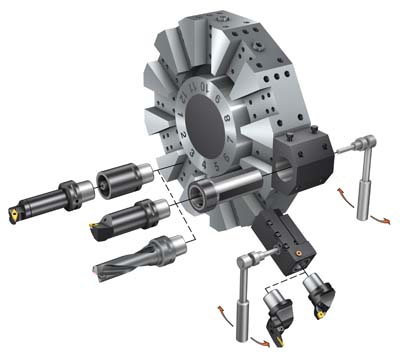

With the new quick change clamping units from Sandvik Coromant you can maximize the amount of actual machining time on your machine. The clamping units utilize Sandvik Coromant's quick change tooling system, Coromant Capto, which has been proven to dramatically reduce downtime with setup and tool changing efficiency.

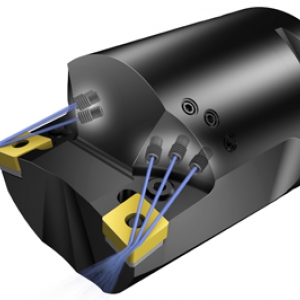

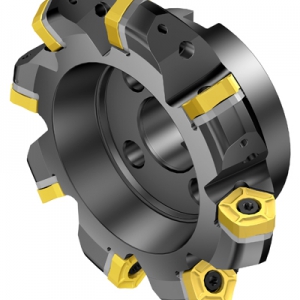

These new products are equipped to channel high pressure coolant from the latest CoroTurn HP cutting heads to reduce temperature and improve chip control. With Coromant Capto Quick Change driven tool holders all application areas can be covered with one clamping unit. The reduced need for dedicated units saves turret space and changeover time.

Products are available from October 1st.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

PRODUCTS

PRODUCTS