Contact Details

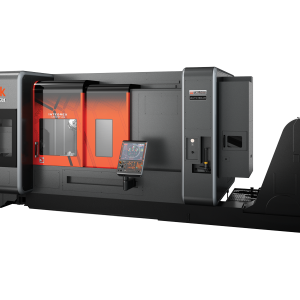

Mazak Corp.'s Quick Turn 450 CNC turning center combines advanced technology, productivity and value to

deliver exceptional part processing for shops large and small. Additionally, Mazak now offers the machine with an optional, powerful 60-hp integral motor main spindle.

The Quick Turn 450’s high-output integral spindle/motor increases mass in the machine’s headstock to reduce spindle vibration during heavy cutting and provide optimal high-accuracy machining. In addition to its standard 50-hp (37 kW), 2,000-rpm spindle with 7.28" (185 mm) bore, the Quick Turn 450 can also accommodate a 60-hp (45 kW), 2,000 rpm spindle with 7.28" (185 mm) bore or a 60-hp (45 kW), 1,000-rpm spindle with 10.8" (275 mm) bore for larger through-hole applications.

A 12-position, direct-drive turret eliminates the use of belts to provide shorter tool index times and reduced maintenance. The machine’s headstock has an optional 18" hydraulic chuck mounted on an optional 60-hp (45 kW), 2,000-rpm integral spindle motor for heavy-duty metal removal.

Available in three bed lengths for maximum machining lengths of 39.45" (1,002 mm), 80.79" (2,052 mm) or 122.13" (3102 mm), the Quick Turn 450 can swing workpieces up to 35.83" (901 mm) in diameter and machine parts up to 22.83” (580 mm) in diameter. The machine also features a fully CNC programmable servo driven tailstock for simple, precise and automatic control of the Z-axis directional movement and thrust force settings. Linear roller guides and rigid machine construction provide positioning accuracy two times higher than the equivalent ISO standard.

The Quick Turn 450 comes standard with Mazak’s Tool Eye, an automatic tool presetting system. By bringing the tool tip into contact with the Tool Eye, offset of tool nose position, tool measurement and data registration are done automatically to ensure accurate and fast tool setup. The Tool Eye can also be programmed to monitor tool wear on a periodic basis.

Mazak’s Mazatrol SmoothG CNC on the QUICK TURN 450 offers the flexibility of both EIA/ISO programming and Mazatrol conversational programming that makes it fast and easy to generate programs for quick changeover or high-production part applications. The controls also feature advanced hardware and software functions that help ensure high productivity and performance accuracy.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- conversational programming

conversational programming

Method for using plain English to produce G-code file without knowing G-code in order to program CNC machines.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS