ROx 400 Absolute Rotary Encoders

ROx 400 Absolute Rotary Encoders

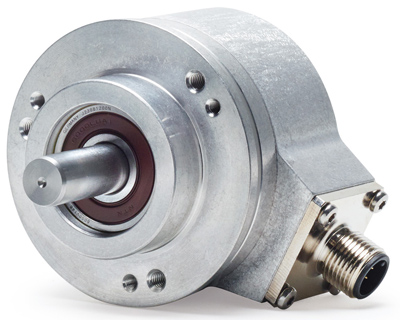

As the demand for functionally safe equipment products grows, so does HEIDENHAIN's component product offerings. Now new to the market are HEIDENHAIN's ROx 400 absolute rotary encoders, available in a functionally safe design including a mechanical fault exclusion for the shaft.

As the demand for functionally safe equipment products grows, so does HEIDENHAIN's component product offerings. Now new to the market are HEIDENHAIN's ROx 400 absolute rotary encoders, available in a functionally safe design including a mechanical fault exclusion for the shaft. Both the synchro and clamping flange versions passed the type testing from TÜV Süd, an international service corporation focusing on consulting, testing, certification and training.

These new HEIDENHAIN ROx 400 encoders are available with a 6mm or 10mm shaft, and equipped with a machined flat to facilitate a positive lock during mounting. A functionally safe mounting scenario requires the mounting flange be secured using M4 screws coated with a materially bonding anti-rotation lock adhesive. To ensure the encoder meets the prescribed PFHd values from the product information, additional specifications for mounting and operation must be adhered to. This additional information for mechanical fault exclusions is available as a supplement to the standard mounting instruction. This document describes things such as required materials for mounting surfaces, proper torque values, acceleration restrictions, as well as storage information.