Contact Details

SigmaNEST, a leading innovator in CAD/CAM, shop floor, and business software for the fabrication industry, is pleased to announce version 24 of the software suite. The new release gives fabricators the tools to reach higher productivity throughout the shop, while being easy and intuitive to use. SigmaNEST 24 suite helps users in three ways: Deeper software integration, a more effective UI, and CAD/CAM enhancements that drive predictably high-quality output at the machine.

Deeper integration streamlines a Connected Shop workflow

The ability to share quoting and job metadata, part data, and material inventory across the entire platform and the ERP system is crucial for smart operations.

A new SigmaBEND AP integration improves the automatic transfer of bending data for part creation, time estimation and quoting into the Connected Shop. Bend programmers will experience a faster workflow for importing parts within SigmaNEST along with rich part data such as number of bends, materials, and bending cycle time for single or batch parts. The data passes through to estimators for precise quoting and to production managers for easier oversight. Automating this data transfer eliminates user error from mistakes during manual entry.

The new SigmaTUBE 24 for SOLIDWORKS integrates completely with the SigmaNEST platform, including powerful new access to the jobs and inventory system, along with improved quoting, scheduling, and load management capabilities. The integration carries onto the shop floor with the TUBE Feedback application that enables machine operators to signal actual cutting times and reorder for miscut parts. The integration of tubular and linear materials to the database allows users to quote based on nested costs and to allocate scrap as available inventory. Finally, SigmaTUBE SW data can also link to business systems for cost estimation and reconciliation.

The new SimTrans 24 gives savvy customers and IT personnel the tools needed to customize the data connections that will streamline their operations. With SimTrans feedback export, users can configure the full array of data transactions to update the ERP system on demand.

SimTrans 24 now includes the SimTrans Studio to give customers the flexibility to inspect and diagnose their SigmaNEST/SimTrans environment. The Studio window gives users access to settings for app integrity, SigmaNEST license configurations, databases and plugins, hardware environment, and shortcuts. This central UI lets users quickly and reliably configure and customize their production environment to fit their needs.

More effective UI gives window to higher productivity

The ability to make decisions based on real-time relevant data offers a competitive advantage for fabricators.

SigmaNEST 24 has expanded the Task Dialog to provide greater situational awareness to the NC programmer for handling multiple projects at one time. Within the Task Window, users can create and load jobs, access workspace task reports and apply new commands to multiple tasks. Users can also monitor key statistics such as sheet consumption and scrap percentages. Beta users have reported that the new Task Window cuts programming to a small fraction of the time needed to program each job individually.

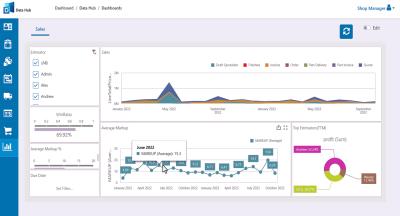

The new Shop Manager 24 lets users create dashboards and KPIs to view on any web browser device. The Sales dashboard gives sales and estimators access to KPIs such as win-loss ratio, average weekly markup, and production pipeline. Production managers can monitor KPIs for material usage, uptime, and number of sheets for each machine in the shop. Programmers can view SigmaNEST program information such as scrap percentage, cut times, material data and programs processed. Shop Manager 24 also makes it easy for IT personnel to administer access levels for various groups across its applications. Individual employees can easily be added within the security groups to user, admin, or restricted access level.

The Quality Manager tab now allows users to log customer complaints for returned or damaged parts. Users can create Non-Conformance Reports (NCR) and Corrective and Preventative Actions (CAPA) for each incidence, and then notify the customer by email. Over time, this record can provide root cause analysis on types of parts, materials, or machines, as well as insights on customer relationships that inform quoting for future jobs.

Version 24 also offers enhancements within the business system software. Estimators can get up to speed more quickly with the new streamlined menu for SigmaQUOTE and SigmaMRP. The simpler clearer interface is easier to learn and customize for any business model. SigmaMRP now gives the ability to set up multiple addresses for a customer delivery as well as automatically apply the local tax rate for delivering to that location.

Stronger CAD/CAM tools

User-friendly tools help programmers drive predictable results at the machine and on the shop floor.

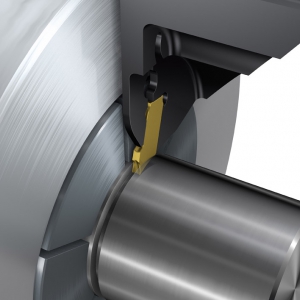

For Laser, Plasma, Oxyfuel and other profile cutting processes, SigmaNEST 24 can now define the part profile sequence for any time that part is cut. This one-time setting at the part level reduces programming effort, improves process reliability, and produces predictable cutting results.

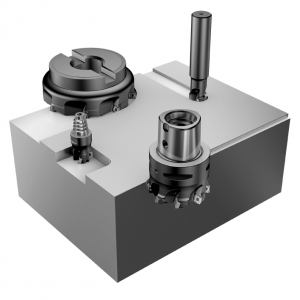

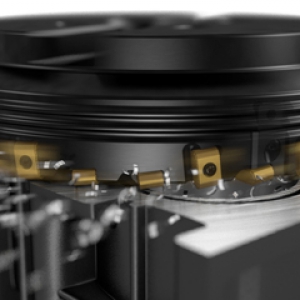

SigmaNEST 24 adds punch tool recognition into the HD SuperNest engine for auto nesting and auto tooling for punch and punch-combi operations. HD SuperNest optimizes the punch tool boundaries to create a tighter nest with a consistent web width, resulting in better sheet stability, higher part yield and quality, and increased machine uptime.

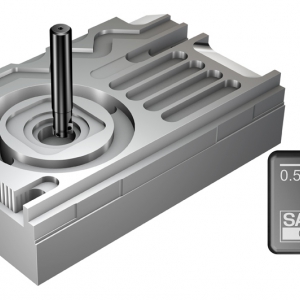

SigmaNEST pattern punching allows programmers to train the software to apply specific tooling for part families with common geometric features. The new Elastic Tooling expansion can detect similar use cases for any part regardless of size and automatically suggests using the specified tooling for that part feature.

A better use of remnants is a vital part of productivity. SigmaNEST 24 features remnant crosshatching to give programmers a quick visual of position, size, and shape, and helps to guide shop floor logistics and storage.

Version 24 enhancements for the 3D CAD/CAM products includes support for rectangular tubing with radius edges. SigmaCTL 24 allows users to create rectangular tubing and automatically recognizes radius edges on imported files.

Commenting on the release, SigmaNEST President Kevin Ramirez said, “The SigmaNEST 24 Suite continues to close the data loop to drive smarter manufacturing specifically for fabricators. The seamless integration of the software creates an easier UI that leverages the data connections for higher productivity.”

Related Glossary Terms

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

PRODUCTS

PRODUCTS