Simply Powerful CAM Software

Simply Powerful CAM Software

GibbsCAM will showcase its latest Simply Powerful CAM software at IMTS 2022 in September. GibbsCAM product experts will be in booth #338880 to highlight the powerful new features of version 2023, which is due to be released just weeks after the show.

GibbsCAM will showcase its latest Simply Powerful CAM software at IMTS 2022 in September. GibbsCAM product experts will be in booth #338880 to highlight the powerful new features of version 2023, which is due to be released just weeks after the show.

GibbsCAM Vice President Nick Spurrett asserts, "We are truly excited to showcase our latest GibbsCAM release. It is packed with features and already receiving really positive reviews from our reseller network and beta program customers."

One of the major developments for this version is the introduction of PrimeTurningTM, a high performance turning strategy for Sandvik Coromant and CoroTurn Prime Type A and Type B inserts which allows optimum feed rate adjustment for accurate cutting in either direction.

GibbsCAM GO Turning can now specify Rake and Back Relief for tool inserts to define the 3D geometry of the tool inserts more accurately. VoluTurn has been updated to include 'Active Chip Thickness Control' which allows the manipulation of the maximum thickness of the chips to increase productivity by optimizing cutting feed rates. Also added is an option for Lathe Drilling with counter-rotating tools which instructs the live tooling spindle to turn in the opposite direction at a specified RPM to increase spindle speed and material removal rates.

The Elliptical Contour process may now be used for elliptical bores inside of solid parts. Thread Turning operations are expanded with Face Threading, Variable Pitch Threading, Multi-pitch, and Position Tool Front options. In addition, a new highly productive tool type, Multifunction Insert Drill, has been added as a periphery insert that can seamlessly switch between turning, lathe drilling, and mill drilling without retraction or tool change motions.

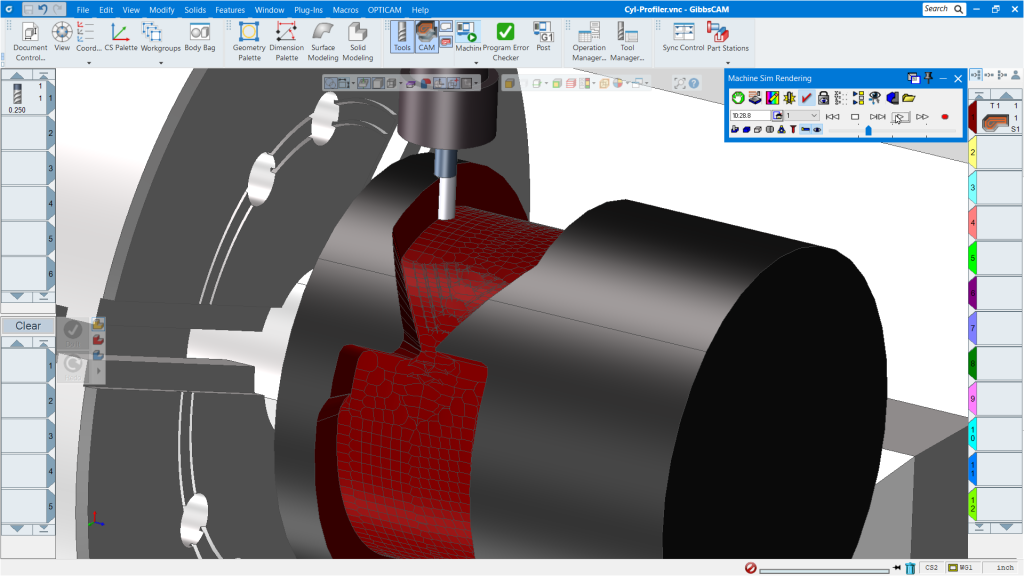

Cylindrical milling in GibbsCAM 2023 is easier with direct selection of a part slice in the depth axis. Select a closed profile to machine a cylindrical boss or pocket, or select two loops to machine a groove or ring.

New Spiral Boring cuts a spiral out to the full diameter at each Z step, which increases cutting feed rate and depth due to a more consistent tool load.

Organizing parts is easier than ever to match the way you work. The ability to earmark parts by work group or coordinate system, create operation groups, and specify active and inactive operations, helps users to track part information throughout the CAM process.

GibbsCAM will exhibit alongside Cimatron in the Machinery Hall booth #338880 as key partners in the Sandvik Design and Planning Automation division. GibbsCAM VP Spurrett confirms, "Sandvik's investment in this business segment represents a commitment toward a greater total solution for manufacturers."

GibbsCAM software programs, simulates, and controls any CNC machine—from 2D to 5-axis milling, turning, Multi-Task Machining (MTM), including Swiss, and wire-EDM. Additionally, GibbsCAM's in-process probing reduces handling for total accuracy, and a comprehensive CNC solution.