Simufact Additive 2020 Software

Simufact Additive 2020 Software

Simufact, part of Hexagon's Manufacturing Intelligence division and a global operating software company providing process simulation solutions and services to manufacturing industries, announced Simufact Additive 2020. This powerful solution for the optimization of metal-based additive manufacturing (AM) processes now provides cost estimation of the build process, and improves interoperability with Materialize build preparation software and Renishaw printers to streamline manufacturing processes.

Simufact, part of Hexagon's Manufacturing Intelligence division and a global operating software company providing process simulation solutions and services to manufacturing industries, announced Simufact Additive 2020. This powerful solution for the optimization of metal-based additive manufacturing (AM) processes now provides cost estimation of the build process, and improves interoperability with Materialize build preparation software and Renishaw printers to streamline manufacturing processes. Based on new technologies, the software also provides higher performance and robustness.

Simufact Additive 2020 expands the scope of manufacturing simulation. In addition to designing and optimizing the build process virtually, users can now estimate print job costs for single components or assemblies. Not limited to the build process, the capability also includes subsequent processes such as cutting, machining, drilling and grinding. This helps the user identify the best build variant by taking into account printing costs.

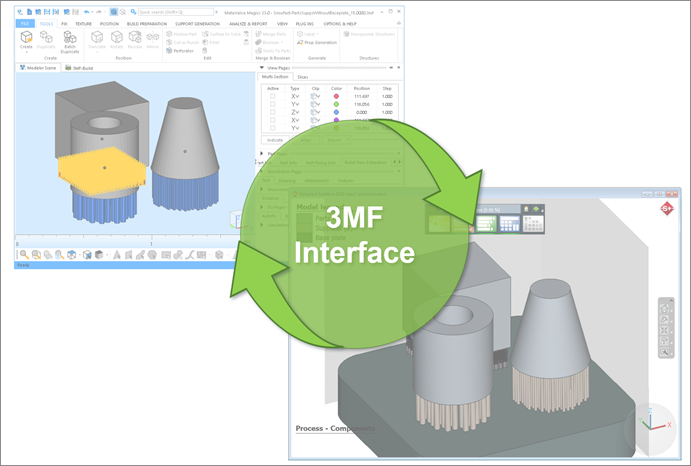

Following Simufact´s efforts to simplify data exchange in the AM process chain, Simufact Additive 2020 now interfaces to Materialize using the 3MF industry standard 3D printing data exchange format. 3MF enables simple and reliable data transfer with third-party software and considerably reduces timely efforts for the model set up.

Simufact Additive 2020 includes an integrated Renishaw QuantAM API for build job preparation and export, which provides the user an error-free-data transmission from Simufact Additive directly to Renishaw printers. This functionality also improves productivity because the entire work process from design to printed part is possible within the software. More interfaces are under development to allowing easy connection to other printing machines.

This new software release applies new Adaptive Voxel Meshing technology to improve the simulation speed by automatically adjusting the voxel sizes in the part. This provides more immediate results to users, and makes the simulation even more reliable and robust.

Another release highlight, Hybrid Manufacturing helps manufacturers to combine Powder Bed Fusion additive manufacturing processes with conventional manufacturing. Simufact Additive 2020 makes it possible to define a given part upon which the printing will begin, including any internal stresses. Thus, stresses and distortions of the complete assembly, and all single parts can be investigated.

Dr. Hendrik Schafstall, CEO and managing director of Simufact, commented: "Simufact Additive 2020 broadens our scope from pure-play process build optimization software to provide cost optimization. This new release also underlines our commitment to openness and interoperability with third-party products. We believe manufacturers should start wherever they want in the process to improve quality and efficiency and make additive manufacturing smarter."