Contact Details

GF Machining Solutions has introduced the Spark Track technology for wire EDMs. Spark Track, powered by the company’s Intelligent Spark Protection System (ISPS) module, prevents wire breakage that occurs when cutting irregularly shaped workpiece features. With Spark Track technology and the ISPS module, wire EDM users gain secure and uninterrupted EDM processing, improved machining efficiency and ease of use for operators.

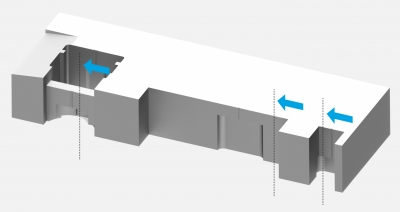

The GF Machining Solutions Spark Track technology, which won the 2019 Prodex Award that honors pioneering products, harnesses modern electronics – sensor signal, speed and effectiveness – to constantly monitor the spark distribution along the EDM wire. Based on the spark data gathered, the ISPS analyzes and automatically recognizes shape changes and adapts machining parameters accordingly to prevent wire breakage during roughing. As a result, irregular shapes such as cavities, varying heights, taper surfaces and sharp corners are easily roughed without the need for operator intervention to set up machining conditions in advance.

As a result of the highly secure EDM process enabled by Spark Track, customers can benefit from 100 percent automation, which in turn reduces the cost per part.

Angled part surfaces are a prime example of where Spark Track and the ISPS module bring high efficiency to the wire EDM process. Such tapered surfaces can create non-homogenous flushing conditions at a wire EDM’s upper nozzle, disrupting the machining process. The ISPS module eliminates the need for the machine operator to adjust the machining process to accommodate such difficult machining conditions since the technology analyzes the spark distribution data, automatically recognizes the shape change and adjusts the process to increase machining efficiency.

Related Glossary Terms

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- wire EDM

wire EDM

Process similar to ram electrical-discharge machining except a small-diameter copper or brass wire is used as a traveling electrode. Usually used in conjunction with a CNC and only works when a part is to be cut completely through. A common analogy is wire electrical-discharge machining is like an ultraprecise, electrical, contour-sawing operation.

Additional Products from GF Machining Solutions

Pagination

- First page

- Previous page

- 1

- 2

- 3

- 4

- 5

- 6

PRODUCTS

PRODUCTS