Contact Details

The Speroni MAGIS benchtop tool presetter is now available in a CNC version for operator-independent measuring results. Latest-generation electronics and motors allow for fast movement and repeatable positioning of the X and Z axes and spindle, delivering full CNC measuring with uncertainty of the two linear axes of +/- 1 µm. With the MAGIS CNC, users can automatically execute measuring cycles, adding speed and precision to what’s already one of the most intuitive and easy-to-use vision system tool presetters on the market.

The included Speroni original workbench provides an enclosed, yet ventilated, storage area with a lockable door to prevent any tampering with your presetter PC. Additional bench features include molded pockets for inserts and screws, storage for various wrenches, and holders for multiple reduction sleeves and other accessories.

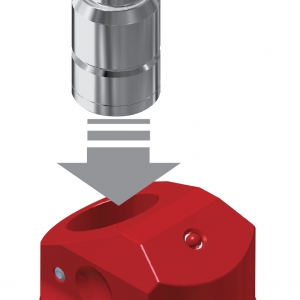

Standard features like thermally-stable pearlitic class 40 cast iron construction, a tool management database storing data for unlimited tool assemblies, 270-degree access to the tools while in the spindle and sub-pixel and sub-micron resolution all support unmatched accuracy and repetitive positioning and assembly. The MAGIS series is also the only bench-top presetter in the world available with an optional built-in Retention Knob Clamping, which provides a strong and repeatable seating in the spindle, mimicking that of the machine tool.

The unit also comes standard with a progressive scan CCD camera with high accuracy telecentric optics with virtual magnification of 45x – with a powerful zoom function for quick zoom up to 120x. Additionally, an Episcopy Front Ring Light system provides a light source for manual inspection of the tool tip/insert on the vision screen. The system is complete with a variable adjustment knob for the proper inspection of the different types of coated inserts.

The MAGIS CNC has a standard X axis range of -2.00 inches (-50mm) to +14.00 inches (+350mm) and is available in three column sizes, with 16-inch (400mm), 20-inch (500mm), and 24-inch (600mm) travel in the Z axis, making it suitable for most offline tool measurement and presetting needs.

The Speroni MAGIS CNC revolutionizes the way software is used in offline tool measurement. Software companies add screens, windows and menus in order to give the user more features. Speroni took a simpler approach, combining all of the needed features and functions in a user-friendly, clean and trouble-free single-screen user interface. The CNC version comes standard with Speroni Edge 2.0 software which allows CAM interfacing and is ready to be implemented with RFID systems.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- vision system

vision system

System in which information is extracted from visual sensors to allow machines to react to changes in the manufacturing process.

PRODUCTS

PRODUCTS