Contact Details

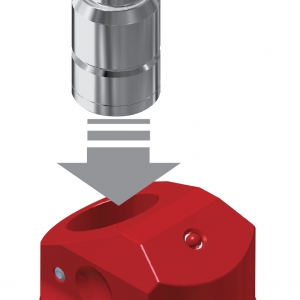

A new deep-hole microdrill from BIG Kaiser's Sphinx line provides a time-saving option for creating wire EDM starter holes, averaging 5X faster per hole according to testing. The addition of this drill to a shop's toolbox replaces the demanding and time-consuming process of plunge EDM to establish a starter hole. This is especially true when a plate requires many starter holes, where they can be prepared on a standard machining center to shorten process times with no need to exchange tools.

With this drill, holes with a length/diameter ratio of up to 80x diameter are possible in the range of 0.25mm-1.50mm, in steps of 0.1mm for hole depths up to 20/40/60/80x diameter. A centering/pilot hole of 2x diameter is recommended to begin the process, with the deep-hole drill following with a peck-cycle until the hole is completed.

The Sphinx deep-hole microdrill has a flute- and cutting-edge geometry adapted to this difficult application. Taking in to consideration wear and tear, the drill is constructed of the appropriate high-quality carbide and optimum abrasion-resistant coating for drilling starting holes in high-strength alloyed tool steels.

Testing and development of this drill by BIG Kaiser's Swiss partner, Sphinx, was done in cooperation with clients specializing in moldmaking.

Related Glossary Terms

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- tool steels

tool steels

Group of alloy steels which, after proper heat treatment, provide the combination of properties required for cutting tool and die applications. The American Iron and Steel Institute divides tool steels into six major categories: water hardening, shock resisting, cold work, hot work, special purpose and high speed.

- wire EDM

wire EDM

Process similar to ram electrical-discharge machining except a small-diameter copper or brass wire is used as a traveling electrode. Usually used in conjunction with a CNC and only works when a part is to be cut completely through. A common analogy is wire electrical-discharge machining is like an ultraprecise, electrical, contour-sawing operation.

PRODUCTS

PRODUCTS