Contact Details

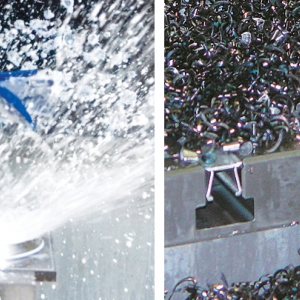

BIG KAISER Precision Tooling introduces the Nirox high-performance drill from Sphinx, the newest addition to its cutting tool lineup. Available in diameters from 0.30-3.00mm, the Nirox was developed for use at low cutting speeds in unstable environments. The Nirox geometry has a degressive helix angle equal to 30 degrees at the point and is designed for accurate and precise hole location up to 9xD.

A modern, TiAlSiN based coating allows for enhanced chip and coolant evacuation in difficult to machine and adhesive materials, such as titanium, Inconel, stainless steel, hardened steel and CoCr alloys.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- helix angle

helix angle

Angle that the tool’s leading edge makes with the plane of its centerline.

PRODUCTS

PRODUCTS