Spindle Speed Increaser

Spindle Speed Increaser

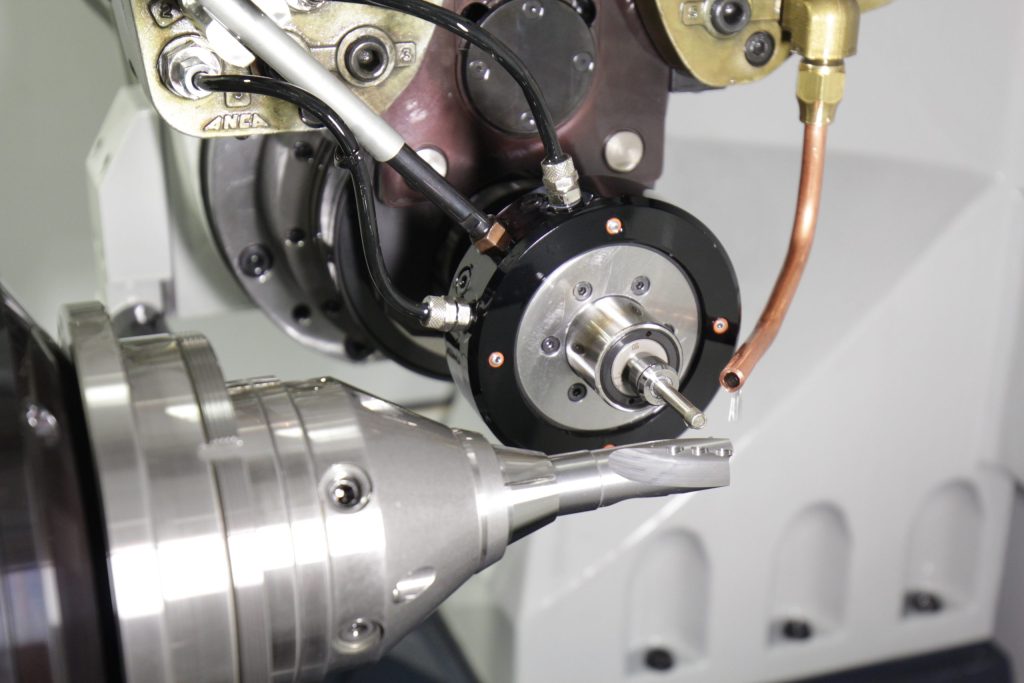

Toolmakers can now easily grind small PCD insert pockets in one simple process. The new Spindle Speed Increaser from ANCA enables customers to easily grind PCD tool blanks, allowing for greater speed and efficiency.

Toolmakers can now easily grind small PCD insert pockets in one simple process. The new Spindle Speed Increaser from ANCA enables customers to easily grind PCD tool blanks, allowing for greater speed and efficiency. Available as an accessory to the TX7 or TXcell, the Spindle Speed Increaser can spin wheels at speeds up to 42,000 rpm, catering for small-diameter grinding wheels.

Duncan Thompson, ANCA product manager said: "Our customers wanted the flexibility to use grinding wheels of under 10mm diameter, so we have introduced the new Spindle Speed Increaser to meet this need. Getting the right wheel surface speed is a critical factor in efficient grinding applications and this new accessory will enable our customers to create high quality tools across an even bigger range of applications.

"As the name implies, its geared mechanism increases the main machine spindle rpm to a maximum of 42,000 rpm. Conveniently, the speed increaser can be changed out automatically in the same way as a regular wheel pack. This means it can be used in conjunction with other grinding wheel packs facilitating a wider range of grinding operations."

In the example of a PCD tool blank preparation, a standard wheel pack and RPM can be used for typical operations such as fluting and relief, while the speed increaser accessory can be used to grind the smaller PCD pockets. This means all operations only require one machine setup to manufacture a completed tool, saving time and increasing efficiency. To complement this, ANCA provides dedicated PCD pocket software that allows the user to quickly and easily define PCD pocket geometry on a given tool.

Duncan continues: "The spindle speed increaser combined with the PCD pocket software is just another option for you to consider new ways to enhance the opportunities for getting maximum value out of your machine tool investment."

The spindle speed is available as an accessory on new or existing TX and MX range of machines. It requires no special changes to a standard TX7 or TXcell, adapting directly into the main spindle's big plus taper system.