Contact Details

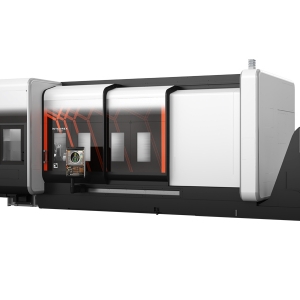

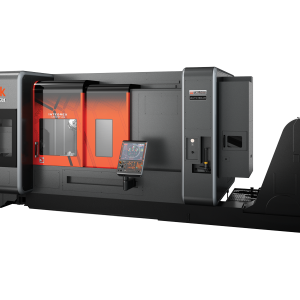

Mazak Corp. offers the SQR-250 turning center for the fast, accurate production of long shaft or chucked workpieces. The machine features a powerful single spindle with two 45-degree opposed-wedge style turrets that cut simultaneously to slash cycle times and provide balanced cutting.

The upper and lower turrets efficiently perform OD and ID operations or OD and drilling. The 12-position upper turret and eight-position lower turret combine for 20 total tool stations. Toolholders can be quickly mounted or removed from the turret by just turning a single bolt, and tools are changed via high-speed turret clamping/unclamping and non-lift indexing.

The spindle on the SQR-250 accommodates a 10" chuck and incorporates integral spindle technology to minimize vibration during high speed operation for superior part surface finishes. A 30-hp motor delivers a maximum speed of 4,000 rpm. With two bed lengths available, the machine handles parts up to 40" in length and 14" in diameter.

The SQR-250’s Mazatrol SmoothG CNC with innovative programming, performance and monitoring functions, as well as the ability to use both EIA/ISO and conversational programming, bring optimal speed and accuracy to complex part production.

Advanced hardware – including a pivoting CNC panel and intuitive, 19" multi-touch LCD control screen – allows for complete ease of use, while a SDHC memory card stores up to 32GB of program data.

The SQR-250 also features Thermal Shield, an automatic compensation for room temperature changes that enhances machining accuracy. Room temperature and compensation data are displayed on the SmoothG CNC screen, allowing machine operators to easily make adjustments when needed.

To further enhance productivity, the SQR-250 can be paired with a gantry loader, bar feeder and other automation equipment for continuous production.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- conversational programming

conversational programming

Method for using plain English to produce G-code file without knowing G-code in order to program CNC machines.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS