Contact Details

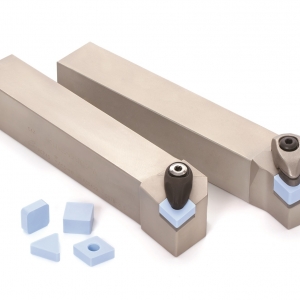

Tungaloy introduces an indexable thread milling solution for tapered pipe threads to its ThreadMilling series. The indexable thread milling system of ThreadMilling allows various types of threading insert(s) to be fitted on a single cutter body, making the operations extremely economical. With the new multipoint threading inserts and cutter bodies, thread milling for NPT and NPTF threads as well as BSPT thread are now possible on machining centers, using its spiral interpolation feature.

Thread milling techniques, in many respects, offer greater advantages over tapping with reduced cutting loads for higher reliability. Solid carbide taps pose higher risk of tool breakage, while HSS taps offer shorter tool life. In addition, insert screws are designed not to detach from the cutter body when completely loosened during insert setup so operators will have no concern dropping or losing the tiny screws in the machine.

At a Glance:

3 types of tapered threads are available: NPT (for 11.5 and 14 TPIs) and NPTF (for 14 TPI) of the U.S. standard, as well as BSPT (for 11 and 14 TPIs), which is common in Asian markets

Provides higher reliability and longer tool life over tapping method

Eliminates concerns for dropping or losing tiny insert screws during tool setup

2 cutter bodies and 5 inserts to be introduced

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

PRODUCTS

PRODUCTS