Contact Details

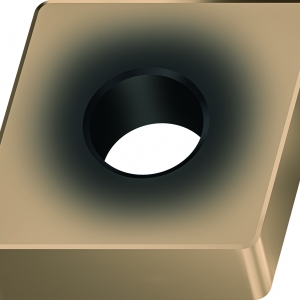

Walter has introduced Tiger·tec® Gold inserts, specially designed for turning operations in all steel applications including low carbon steels as well as various alloy steels. A key feature of these inserts for turning is their outstanding process reliability. This, along with their performance and tool life, is the result of their unique layer structure: A patent-pending, highly textured MT-TiCN layer reduces flank face wear and increases toughness due to its multi-layered elastic structure. A highly textured Al2O3 layer additionally increases the product's resistance to crater wear, while the gold-colored top layer helps improve wear detection.

The final multi-stage proprietary post-treatment of the inserts ensures a rake face with reduced friction for easy chip evacuation and a high level of substrate toughness for resistance to chipping and notching. With this new technology, Walter is introducing three new CVD grades. The WPP10G has the highest wear resistance for continuous cuts primarily in steels (ISO P10) and secondarily in cast irons (ISO K20). The WPP20G is the universal grade capable of handling a wide range of applications, including continuous cuts to moderately interrupted cuts in steels (ISO P20) and with secondary applications in cast irons (ISO K30).The WPP30G is the toughest grades for steels (ISO P30) and secondary applications in cast irons (ISO K20) respectively. Being the toughest grades, WPP30G also is ideal for heavy interruptions, castings with scale, older unstable machine setups or any other applications that require a tough grade. Walter has introduced these grades after a wide range of tests performed globally, with an average tool life increase recorded at 50% higher over any previous generation technology in the market.

The primary application of these new Tiger·tec® Gold inserts is steels with various tensile strengths that can be machined. These indexable inserts are ideal for use in the automotive, energy, and general metalworking industries, where the inserts can significantly help reduce the cost per component. Walter is offering Tiger·tec® Gold indexable insert grades with its signature geometries starting with finishing (FP5), medium machining (MP3, MP5, MU5) all the way to roughing (RP7, HU5), etc. along with some other niche geometries for specialist troubleshooting purposes.

Related Glossary Terms

- alloy steels

alloy steels

Steel containing specified quantities of alloying elements (other than carbon and the commonly accepted amounts of manganese, sulfur and phosphorus) added to cause changes in the metal’s mechanical and/or physical properties. Principal alloying elements are nickel, chromium, molybdenum and silicon. Some grades of alloy steels contain one or more of these elements: vanadium, boron, lead and copper.

- carbon steels

carbon steels

Known as unalloyed steels and plain carbon steels. Contains, in addition to iron and carbon, manganese, phosphorus and sulfur. Characterized as low carbon, medium carbon, high carbon and free machining.

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS