Contact Details

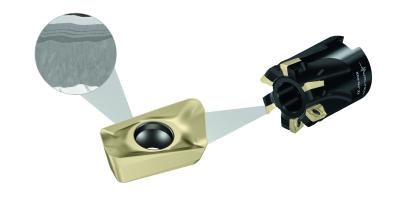

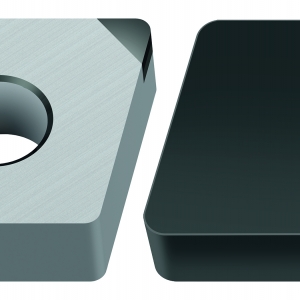

Walter is expanding its Tiger·tec® Gold range with the new WSM35G milling grade. The indexable insert is coated with the only PVD Al2O3 coating technology of its kind to date with a multi-layer structure on a carbide substrate. The structure consists of a bottom TiAlN layer for high wear resistance, a middle Al2O3 layer for high temperature resistance and a ZrN gold-colored top layer for minimized friction and the best wear detection.

The new coating ensures excellent cutting-edge stability and therefore a long tool life, as well as high process reliability, even in complex applications.

The grade WSM35G is for universal application even under abrasive and difficult conditions, such as interrupted cuts or during wet machining, when milling austenitic stainless steel or nickel-based superalloys (ISO M and S workpiece groups).

The new grade is Walter’s response to the upwards trend towards milling steel with difficult machining properties and wear-resistant stainless steel, such as found in applications in the energy and aviation industries. WSM35G meets the most stringent requirement for process reliability, which is highly valued in the automotive sector, and is also suitable for general mechanical engineering applications.

Successful applications include milling aircraft engine components made of Inconel or titanium and machining high-temp automotive engine and turbocharger parts. In these applications, Walter’s grade WSM35G increased tool life 30% or more compared to previously used cutting tool materials.

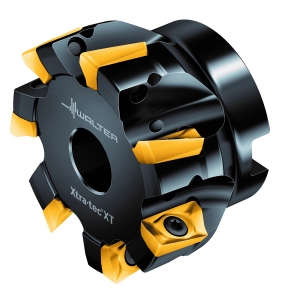

This new grade has been applied to inserts for all standard milling cutters in the Walter lineup, such as the Xtra·tec XT M5130 shoulder milling cutter, and many more.

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- cutting tool materials

cutting tool materials

Cutting tool materials include cemented carbides, ceramics, cermets, polycrystalline diamond, polycrystalline cubic boron nitride, some grades of tool steels and high-speed steels. See HSS, high-speed steels; PCBN, polycrystalline cubic boron nitride; PCD, polycrystalline diamond.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS