Contact Details

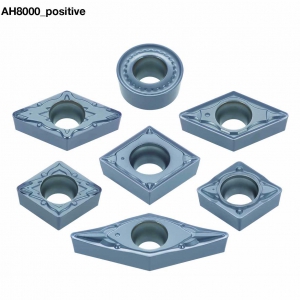

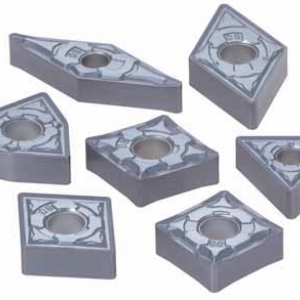

Tungaloy Corp. offers TungForce-Rec, the indexable miniature shoulder milling cutter. The TungForce-Rec insert has a unique V-shaped bottom to enhance the insert’s resistance to centrifugal force, assuring reliability and high productivity during high-speed machining, according to the company. A large positive inclination angle also reduces cutting force, while the insert flank is uniquely designed to increase chipping resistance.

Miniature shoulder mills, in general, tend to have a thin body core due to limited insert positioning. TungForce-Rec, on the other hand, has a thick core due to the insert’s V shape. Integrating the cutter body with the inserts completes the cutter’s full rigidity, thus making it suitable for a range of applications. TungForce-Rec is also recommended for 3D profile milling in addition to shouldering and slotting.

The periphery ground insert is applicable for a depth of cut up to 0.23” (6 mm). The insert grades are available in three types according to materials to be worked with. The tool diameter ranges from 0.313” to 0.625” (and in metric sizes from 8 mm to 16 mm).

Related Glossary Terms

- cutting force

cutting force

Engagement of a tool’s cutting edge with a workpiece generates a cutting force. Such a cutting force combines tangential, feed and radial forces, which can be measured by a dynamometer. Of the three cutting force components, tangential force is the greatest. Tangential force generates torque and accounts for more than 95 percent of the machining power. See dynamometer.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- inclination angle

inclination angle

Angle that the cutter edge makes with a plane that is perpendicular to the direction of tool travel. Determines the direction the chip curls.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

PRODUCTS

PRODUCTS