Contact Details

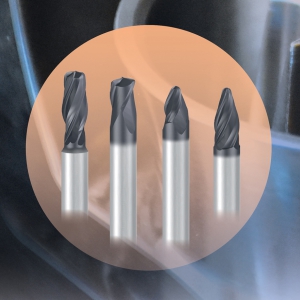

Emuge Corp. has introduced an advanced line of endmills featuring unique geometry designed specifically for the high-performance machining of turbine and bladed components. New Emuge Turbine End Mills offer unprecedented cycle time reductions and long tool life in challenging forms and materials, including titanium, nickel alloys, aluminum alloys and more.

Complex shapes including wide sweeping radii and deep pocketed cavities present ample challenges for aerospace and turbine manufacturers. "We are very pleased to offer our customers a solution to meet the unique requirements for milling turbine parts, as well as for the die and mold industry, " said Dan Doiron, milling product manager, Emuge Corp. Mold applications include machining tire molds and plastic injection molds, among others.

Suitable for machining components with challenging geometries, new Emuge Turbine End Mills have a stable design including on the tools featuring a tapered flute construction. The endmills feature PVD-applied, highly hard and heat-resistant coatings, and a newly developed geometry that enables aluminum machining.

The Emuge Turbine End Mills Line includes a wide range of taper ball tools that feature a submicrograin carbide substrate and an HA cylindrical shank. The 3°, 4°, 6° and 8° taper ball tools have 2- and 3-flute designs, and the 17.5° has 3 flutes. Polished flutes in the 3°, 4°, 6° and 8° tools promote chip evacuation in aluminum alloys. Coating options for the taper -all tools include AlCR for additional tool life in titanium alloys, high-temperature alloys, stainless steel and aluminum alloys, and TiAlN for heat and abrasion resistance in a wide range of materials such as stainless steel, steel alloys, cast iron and other ferrous metals.

Taper Torus endmills include 3°, 4°, 6° and 8° sizes featuring 2 highly polished flutes, submicrograin carbide, and have a torus "cupped" radius end design for maximum step-over lengths. AlCR coating is standard, and TiAlN coatings are available.

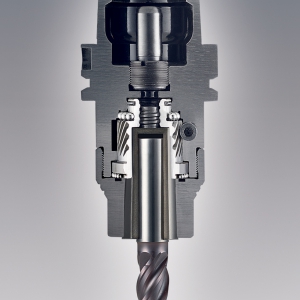

A long 8° taper torus style also features a torus cupped radius. The cutting flutes are tapered for increased efficiency in a range of designs from 5 to 15 flutes. The tools are TiAlN coated for maximum tool life and include axial coolant through capability.

The Emuge Turbine End Mills Line includes a torus long-length tool style, which features variable flute spacing for low-vibration milling. The tools are available in designs ranging from 5 to 9 flutes and have a corner radii of 1.0 or 2.0 mm. Torus long length endmills are TiAlN-coated for maximum tool life and include coolant-through capability.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- aluminum alloys

aluminum alloys

Aluminum containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. Aluminum alloys are divided into two categories: wrought compositions and casting compositions. Some compositions may contain up to 10 alloying elements, but only one or two are the main alloying elements, such as copper, manganese, silicon, magnesium, zinc or tin.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- step-over

step-over

Distance between the passes of the toolpath; the path spacing. The distance the tool will move horizontally when making the next pass. Too great of a step-over will cause difficulty machining because there will be too much pressure on the tool as it is trying to cut with too much of its surface area.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

PRODUCTS

PRODUCTS