Contact Details

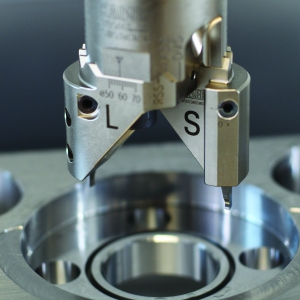

The worlds of workholding and automation collide with the addition of Unilock's new ESA 120/70 automation chuck from BIG Kaiser Precision Tooling Inc. Unilock is known for reducing setup and changeover costs, but until now, the standard knob program was limited when it came to automation. The new automation chuck series changes that by allowing for an intelligent interface and communication back to the controller using the standard Unilock knobs that thousands of customers already have implemented, according to the company.

Table integration of the ESA 120/70 chucks allows robots to pick and place fixtured workpieces into the machine. The system checks for workpiece presence, proper orientation and clamping, and then communicates back to the controller when the workpiece is in place and ready to be machined. On the flipside, when a part is finished and removed from the work envelope, the machine knows nothing is loaded and will not allow a new cycle to start until a new component is properly in place.

Of course, cleanliness of mating surfaces is of upmost concern during automated loading. The top surface of the ESA 120/70 has self cleaning capability through an air blast originating off the chuck's contact surface as the workpiece nears. Additionally, a slot was designed through the chuck that allows coolant or chips to flow out of the center clamping area and away from the precision locating features. For increased retention forces, the turbo assist feature boosts the clamping force to a max 1,870 lbs, compared to the max 660 lbs without it.

As typically seen with most chucks that utilize the standard Unilock knobs, the system has an impressive locating repeatability of .0002" and a holding force of 11,240 lb.

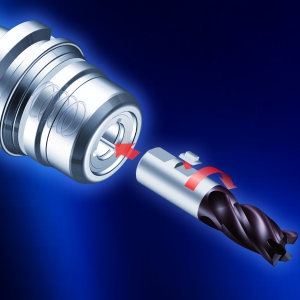

The Unilock system is a comprehensive positioning and clamping system that can be applied to almost any manufacturing or assembly process for a boost in productivity, bringing customers higher efficiency and agility. By automating the system, customers can achieve even higher levels of productivity without the need for constant human intervention.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- work envelope

work envelope

Cube, sphere, cylinder or other physical space within which the cutting tool is capable of reaching.

PRODUCTS

PRODUCTS