Contact Details

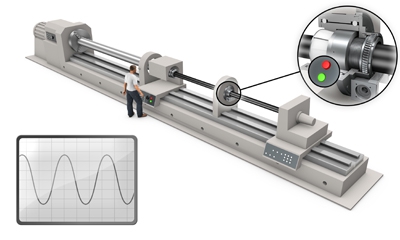

Sandvik Coromant has introduced a new vibration damper that helps to maintain stable production during Deep Hole Machining (DHM) operations and support increased machine tool utilization. Using the machine control adjustment unit, the new device allows operators to step away from the machine and manage process modification without hand tools or the risk of personal injury.

High material removal rates and precision are the defining characteristics when it comes to DHM, along with hole straightness, dimensional tolerances and surface finish. With this in mind, it comes as little surprise that security is paramount to success.

When producing long parts on STS (Single Tube System) machines, operators face a number of process-critical challenges. Many DHM operations are extremely demanding, pushing machining performance to the limit. This can generate higher forces and stresses within the tooling system, which in turn can become problematic in terms of vibration. As a consequence, operators are often faced with manual adjustment of the clamping unit on the vibration damper. When a large workpiece is rotating, adjusting the clamp by hand is not a straightforward operation. It is difficult to get right immediately because of the accuracy needed. What's more, the risk of injury is elevated considerably.

The Sandvik Coromant vibration damper provides the solution. The device dampens vibration, leading to first class precision and surface finish. In addition, it does this using the machine control, facilitating a stable production process, safely. There is even a self-locking unit in the event of a power loss. Of course, when vibration is under control, another benefit arrives in that excessive tool wear is no longer an issue. The result is increased machine uptime and a safer working environment.

The new vibration damper from Sandvik Coromant offers bi-directional functionality ensuring it can be deployed for both push and pull applications.

Additional Products from Sandvik Coromant Co.

Pagination

- First page

- Previous page

- …

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

PRODUCTS

PRODUCTS