Contact Details

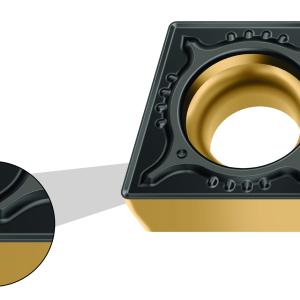

The new Walter Cut G1511-P grooving tool with precision coolant supply, available in 1.0 in. shank sizes, provides long tool life and high productivity, among other benefits. It is suitable for universal use, performing grooving, parting-off, recessing and face grooving with GX insert cutting widths from 0.024 to 0.250-in. (0.6 to 6.35 mm), and can perform radial and axial grooving operations without loss of stability.

The inserts deliver a cutting depth of up to 0.16 in. (4 mm), with the GX16 series inserts and up to 0.24 in.(6 mm) with GX24 inserts. In addition, after the first groove is cut, the groove can be widened in either direction without limitation. The new grooving tool features precision coolant delivered directly to the cutting zone starting from a coolant pressure as low as 145 psi. It employs a G1/8-in. internal coolant connection and direct coolant transfer (M6 interface) when using A2120/A2121 adaptors.

Walter’s G1511-P grooving tool is designed with a low head height for superior chip evacuation, and a Torx Plus screw that can be accessed from above or below the tool. It provides users with cycle time reduction through higher cutting values along with reliability and versatility, which translates into fewer time-consuming toolholder changes, a feature which is particularly attractive for job shops with short run production.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- recessing

recessing

A turning operation in which a groove is produced on the periphery or inside a hole of a workpiece. The grooving tool moves at right angles to the axis of rotation.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

PRODUCTS

PRODUCTS