Walter Helitronic Power 400 and Helitronic Power Diamond 400

Walter Helitronic Power 400 and Helitronic Power Diamond 400

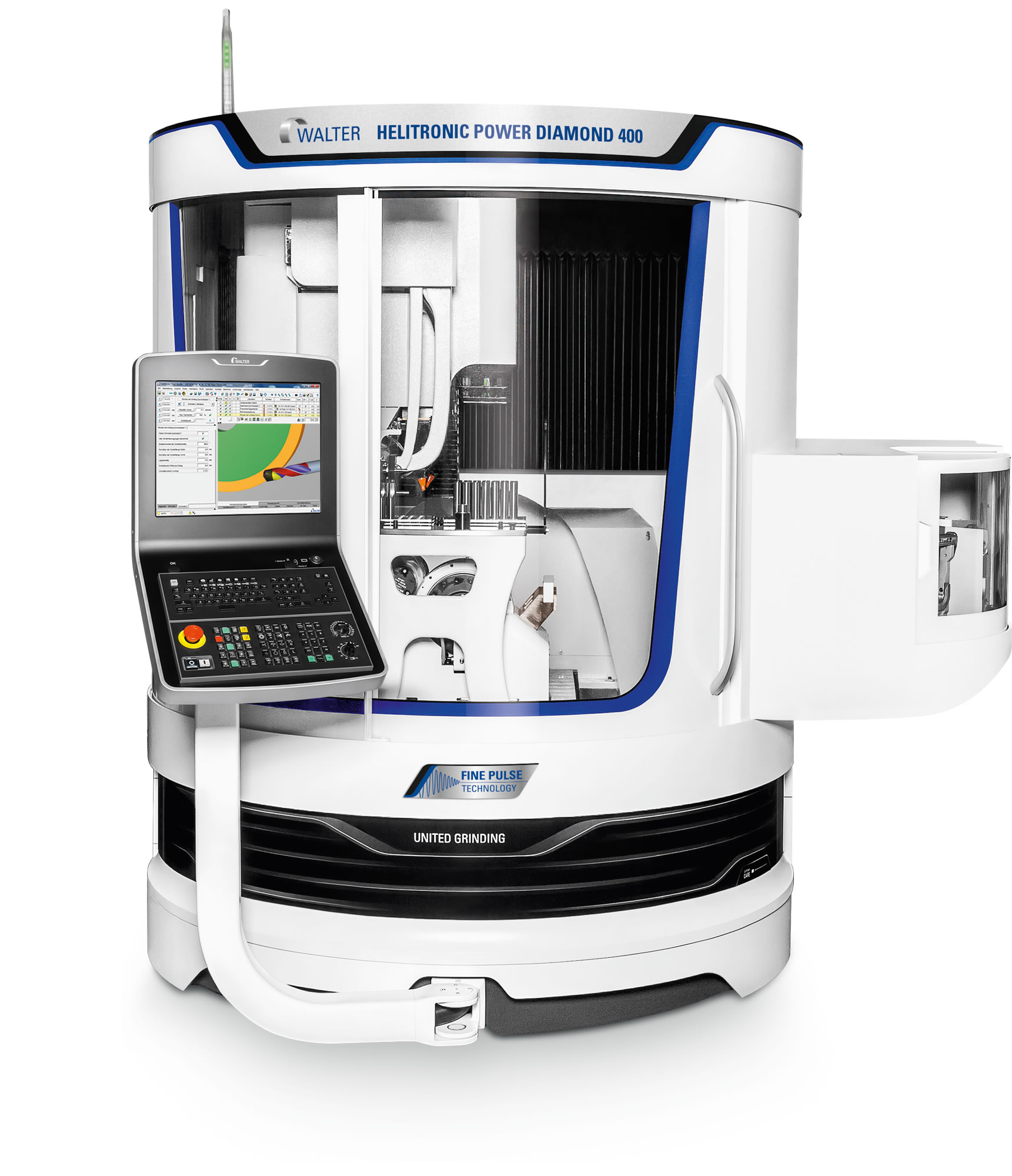

United Grinding Group offers its newly redesigned Walter Helitronic Power 400 grinding machine and Helitronic Power Diamond 400 grinding and eroding machine.

United Grinding Group offers its newly redesigned Walter Helitronic Power 400 grinding machine and Helitronic Power Diamond 400 grinding and eroding machine.

"The new Helitronic Power 400 grinding machine and Helitronic Power Diamond 400 are more in line with our Helitronic Vision models," said Torsten Wörner, product manager at Walter's grinding department. "They're basically two completely new machines."

The two new Helitronic machines offer 35 percent more workpiece space with the capability to grind tools up to 380 mm (14.96") in length. They also feature remodeled machine beds with enhanced rigidity for greater vibration dampening for improved part surface finishes and to ensure greater precision. A new worm drive for the C-axis, optional torque motor and pneumatically driven steadyrests and tailstocks from the Helitronic Vision series all serve to further improve grinding and eroding operations by reducing leaks and improving heat management for greater cleanliness.

Unlike previous models, the new Helitronic Power 400 grinding machine and Helitronic Power Diamond 400 can accommodate gantry-style loaders for up to 500 tools or robot loaders for up to 7,500 tools. Another previous Helitronic Vision exclusive, Walter's Robot Loader 25, is now available for the redesigned models as an automation solution for tools weighing more than 25 kg (55.12 lbs).

Like all of Walter's Two-In-One machines, the new Helitronic Power Diamond 400 utilizes Fine Pulse Technology. "For over a year, this technology has been at the forefront when it comes to surface quality, cutting edge toughness and process stability for PCD tools," said Siegfried Hegele, product manager in the eroding department at Walter. Likewise, both machines utilize the Helitronic Tool Studio grinding and eroding software.