Contact Details

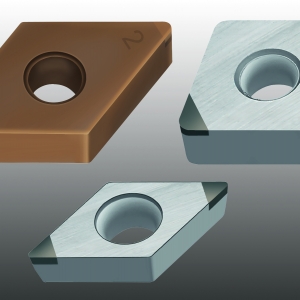

Walter has introduced WEP01C cermet turning indexable inserts with the highly positive, soft-cutting FX4 chip breaker geometry. The indexable insert with fully precision ground circumference is available in four basic shapes: CCGT, DCGT, TCGT and VCGT.

The titanium-carbide-based cermet substrate with the cobalt-nickel binder, is extremely wear resistant. The grade includes an exceptionally hard PVD AlTiCrN multilayer coating, which is very even and smooth to impart the finest surface finish. The multilayer coating provides the ultimate protection against wear, with a layer-bonding to prevent flaking.

Because of the ground chip breaker on these inserts, the inserts are handed (left hand and right hand insert), but these are standard ISO shapes and sizes- so they are held in conventional ISO turning holders. The inserts also use ‘M’ or maximum material condition tolerance on the corner radii of the cermet, thus allowing for machining of small radius shoulders while utilizing maximum (larger) corner radius strength. The primary application for the WEP01C cermet inserts is turning steels and cast irons (ISO P and ISO K material groups). The secondary application is turning stainless steels (ISO M). The indexable inserts are suitable for finishing and fine finishing with continuous cuts and slightly interrupted cuts.

The recommended machining parameters are a feed (f) of 0.001 to 0.010 in. (0.02 to 0.25 mm) and axial depth of cut (ap) of 0.004 to 0.100 in. (0.1 to 2.5 mm).

Potential benefits of the WEP01C cermet indexable inserts include generating visibly shiny surface on the component at high and low cutting speeds, an extremely soft cutting action to prevent vibration and a longer tool life and higher productivity in comparison to carbide inserts. In addition, no cutter compensation is necessary over long periods to cut, to achieve maximum dimensional accuracy. With a multilayer coating, the WEP01C cermet inserts provide maximum wear resistance.

Related Glossary Terms

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- cutter compensation

cutter compensation

Feature that allows the operator to compensate for tool diameter, length, deflection and radius during a programmed machining cycle.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS