February 2011

Articles in this issue

Automated honing boosts production

END USER: Sonic Industries Div., Sargent Aerospace & Defense Group, (310) 532-8382, www.sargentaerospace.com. CHALLENGE: Reduce cycle times while holding criti…

Boosting beam production

END USER: HITCO Carbon Composites Inc., (800) 421-5444, www.hitco.com. CHALLENGE: Increase productivity when machining composite parts. SOLUTION: A 5-axis mach…

No penalty for holding

END USER: Bob's Design Engineering Inc., (503) 648-7418, https://www.bdeinc.com. CHALLENGE: Increase productivity when drilling holes more than 10 diameters de…

Workbench and working comfort basics

Shop Operations column from February 2011 issue of Cutting Tool Engineering magazine discusses the importance of comfortable workbenches and worktables.

Machining strategies for difficult materials

Machine Technology column from the February 2011 issue of Cutting Tool Engineering magazine offers machining strategies for difficult-to-cut materials.

The 10 percent dressing rule

Grinding Doc column from the February 2011 issue of Cutting Tool Engineering magazine explains the 10 percent grinding rule and offers other grinding advice.

Thoughts on acquiring equipment

Manager's Desk column from the February 2011 issue of Cutting Tool Engineering magazine takes a look at various considerations when examining equipment acquisi…

High-Velocity Grind

Strategies for grinding HVOF-coated aerospace parts.

Multisoft

CAM and simulation software packages enable productive programming of multitasking machines—particularly as they become 'ultratasking' machines.

Turning Vertical

Turning a lathe vertical can be a productivity turn for the better—for large and small parts.

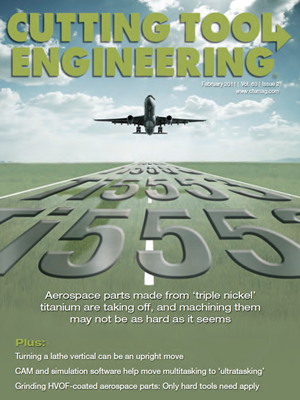

Tackling Triple Nickel

When it comes to milling aerospace parts made from Ti5553, difficulty is in the eye of the beholder.

Machining rings around the competition

Part Time column for February 2011 issue of Cutting Tool Engineering looks at a shop that machines tungsten-carbide wedding, engagement and personal rings.